Pneumatic air hammer is a kind of industrial equipment driven by compressed air to generate knocking. It is widely used in many productions, especially material conveying equipment, silos, feeding equipment, etc. Let’s briefly introduce the working principle of the pneumatic air knocker, also called the pneumatic percussion hammer.

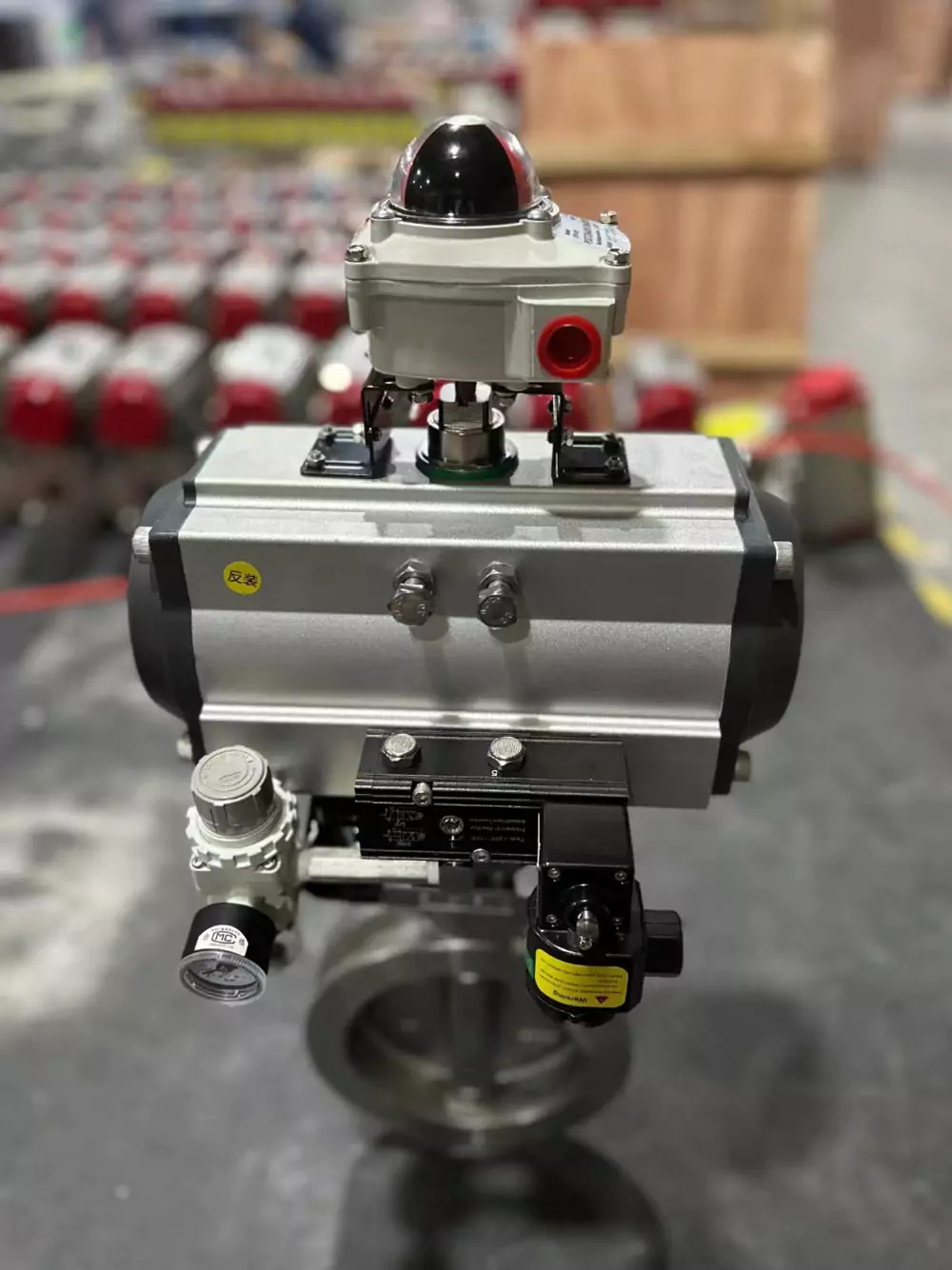

Pneumatic air hammer can effectively prevent the adhesion, blockage and bridging of powder in pipelines, hoppers and silos, without causing damage or deformation to the walls of the equipment. The uniquely designed magnetic piston makes the air hammer have greater impact, and the striking part adopts a new type of high-strength and wear-resistant material – ultra-high molecular weight polyethylene, the shell is made of high-quality cast aluminum alloy, and the control box can adjust the striking Interval time and tap time.

The main features of this product are: strong magnetic impact, good powder falling effect; less air consumption, low operating cost, good energy saving effect; simple structure, easy disassembly; novel and unique appearance design, impact resistant piston, and explosion-proof, widely applicable Pesticides, medicines, paints, dyes, pigments, food, electronics, building materials, minerals, drying, storage and other industries, it is a powerful arch-breaking and flow-aiding device for powder processing production lines.

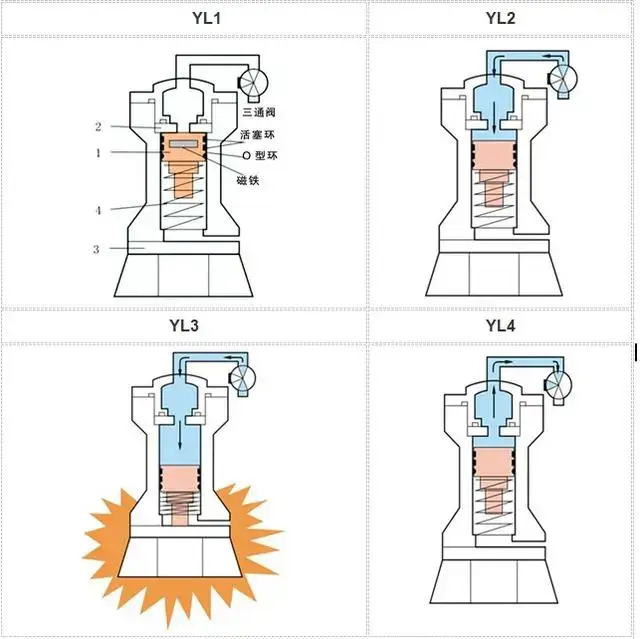

Working principle: When the air hammer is not supplied with compressed air, the magnetic piston is tightly attracted to the base plate by means of strong magnetic force. When the two-position three-way solenoid valve is energized, compressed air (greater than 3Kg/cm2) flows into the air hammer , when the pressure is greater than the magnetic force, the piston hits the pedestal at high speed, and its impact force is transmitted to the warehouse wall, or it directly hits the warehouse wall to generate vibration to achieve the purpose of shaking off the powder. When the two-position three-way solenoid valve is powered off, the compression The air is discharged through the solenoid valve, so the piston returns by the elastic force of the spring. When it is close to the substrate, the magnetic force makes the piston and the substrate tightly attracted together, returning to the original state. In this way, one impact stroke is completed. By adjusting the time relay in the electrical control box, you can reduce or increase the tapping interval and tapping time.

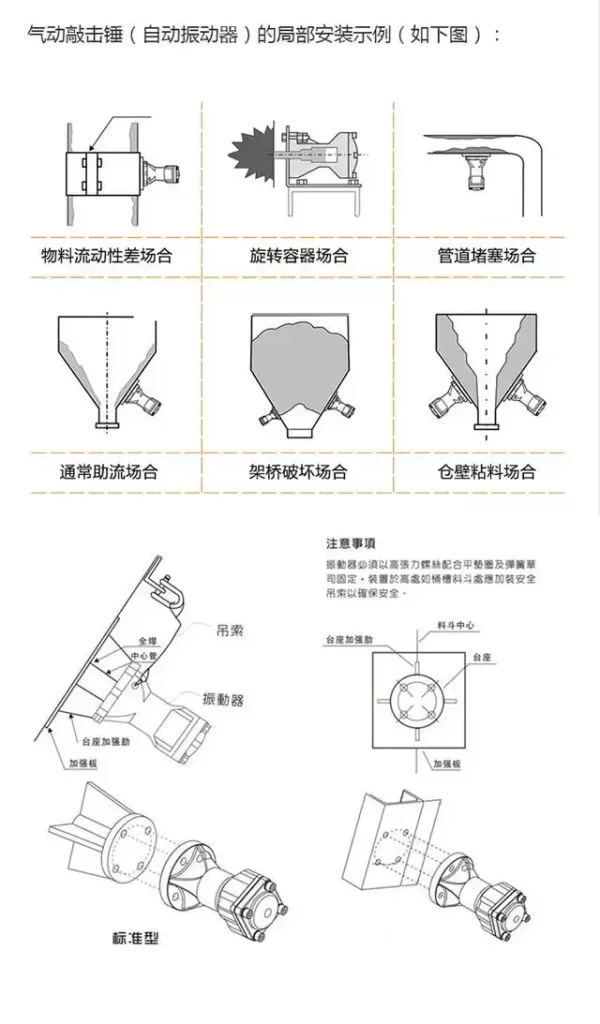

Pneumatic hammers are widely used, mainly in powder, dust removal, coal, transportation, pharmaceutical and other industries. The purpose of the work is to prevent and solve the phenomenon of material sticking to the wall, bridging and blockage in the silo and equipment, and can effectively solve the problem of slow flow rate or normal feeding during production.