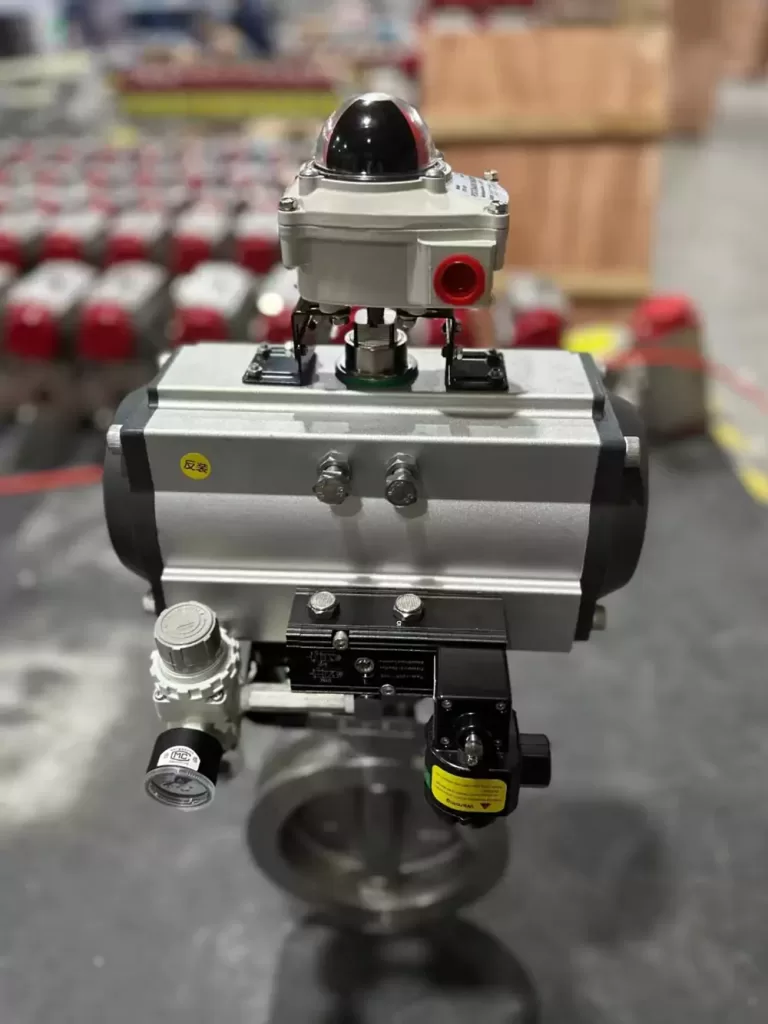

The pneumatic butterfly valve is composed of a pneumatic actuator and a butterfly valve. The pneumatic butterfly valve is a pneumatic valve that uses a circular butterfly plate that rotates with the valve stem to realize the opening and closing. It is used more and more on medium-bore pipes. Pneumatic butterfly valve classification: stainless steel pneumatic butterfly valve, hard seal pneumatic butterfly valve, soft seal pneumatic butterfly valve, carbon steel pneumatic butterfly valve. The main advantages of the pneumatic butterfly valve are simple structure, small size, lightweight, and low cost. This characteristic of the pneumatic butterfly valve is particularly remarkable. It is installed in the high-altitude dark passage, and it is easy to operate through the control of the two-position five-way solenoid valve, and the flow medium can also be adjusted.

The main advantages of the pneumatic butterfly valve are simple structure, small size, lightweight, and low cost. This characteristic of the pneumatic butterfly valve is particularly remarkable. It is installed in the high-altitude dark passage, and it is easy to operate through the control of the two-position five-way solenoid valve, and the flow medium can also be adjusted. The fluid resistance is small, and the effective flow area of the pneumatic butterfly valve with medium and large diameters is large when fully opened, and the opening and closing are quick and labor-saving. The generated torque is in the opposite direction, so the opening and closing torque is small, and good sealing can be achieved under low pressure. The sealing materials of butterfly valves include nitrile rubber, fluorine rubber, edible rubber, and PTFE lining, so the sealing performance is good. Among them, the hard seal butterfly valve is soft The hard laminated metal sheet has the advantages of metal hard seal and elastic seal, and has excellent sealing performance no matter at low temperature.

Features:

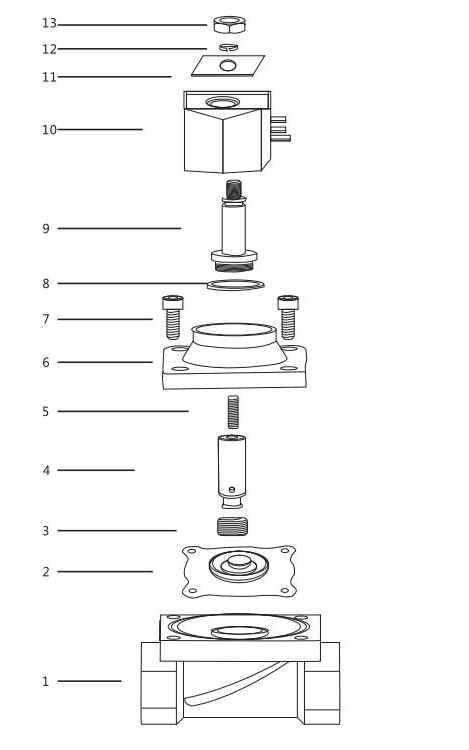

1. Small and light, easy to disassemble and maintain, and can be installed at any position.

2. The structure is simple and compact, the operating torque is small, and the 90°rotation opens quickly.

3. The flow characteristic tends to a straight line, and the adjustment performance is good.

4. The connection between the butterfly plate and the valve stem adopts a pinless structure, which overcomes possible internal leakage points.

5. The outer circle of the butterfly plate adopts a spherical shape, which improves the sealing performance and prolongs the service life of the valve. It still maintains zero leakage for more than 50,000 times of opening and closing under pressure.

6. The seal can be replaced, and the seal is reliable to achieve two-way seal.

7. The butterfly plate can be sprayed with a coating according to user requirements, such as nylon or PTFE.

8. The valve can be designed as flange connection and wafer connection.

9. The driving mode can be manual, electric or pneumatic.

Composition and classification of positioners in pneumatic butterfly valves

The valve positioner is the main accessory of the pneumatic butterfly valve and is used in conjunction with the pneumatic butterfly valve. The valve positioner is a regulator that acts as a proportional magnifier. The valve positioner and the control valve form a valve stroke adjustment system. The main components of this system are an air volume element and a hysteresis element. According to its structure and working principle, the valve positioner can be divided into pneumatic valve positioner, electric valve positioner and intelligent valve positioner. Its role:

1. Eliminate lag;

2. Eliminate incongruity;

3. Used in the compound regulation system;

4. Realize the reverse action;

5. Operate non-standard actuators;

Among them, the pneumatic valve positioner receives the output signal of the pneumatic regulator, and then generates an air pressure signal proportional to the output signal of the regulator to control the pneumatic regulating valve. According to the working principle, it is divided into displacement balance type and torque balance type.

The output signal of the electric valve positioner is DC4-20mA direct current signal, which controls the action of the actuator. It can function as an electrical converter and a pneumatic valve positioner. Colleagues give feedback according to the displacement stroke of the actuator, so that the position of the valve can be correctly positioned according to the control model output by the regulator. This is what the pneumatic butterfly valve uses.

Electric valve positioner. The comparison between the given value and the actual value of the position of the actuator is carried out in the idanzidianlu of the microprocessor. The microprocessor outputs an electric control command to the piezoelectric valve according to the control limit deviation. Piezo valves convert this command into pneumatic positioning increments. If the control limit deviation is large, the piezoelectric valve outputs a continuous signal, if the limit deviation is small, there is no positioning pulse output, and if the limit deviation is moderate, a pulse sequence is output.

Choice of accessories

(1) The accessories of pneumatic butterfly valve mainly include: positioner, converter, relay, booster valve, position valve, pressure reducing valve, filter, lubricator, travel switch, position transmitter, solenoid valve, hand wheel mechanism.

(2) The accessories play the role of supplementary function and ensuring the operation of the valve. Increase what is necessary, and do not increase what is unnecessary. Adding accessories when unnecessary increases the price and reduces reliability.

(3) The main function of the positioner is to increase the output force and the speed of action. If these functions are not needed, it is not necessary to have it. It is better to have a positioner instead.

(4) For the fast response system, don't want the valve to move fast, and the converter is optional.

(5) Strict explosion-proof occasions, optional: electrical converter + pneumatic positioner.

(6) Reliable products should be selected for the solenoid valve to prevent it from not acting when it is required to act.

(7) It is recommended not to use the handwheel mechanism on important occasions to prevent human error.

(8) It is best provided by the manufacturer and the assembly is supplied on the valve to ensure the reliability of the connection between the system and the assembly.

(9) When ordering, the name, model, specification, input signal, output signal, etc. of the accessories should be provided.

(10) To reiterate: Please pay attention to the importance of these "little things", especially reliability.