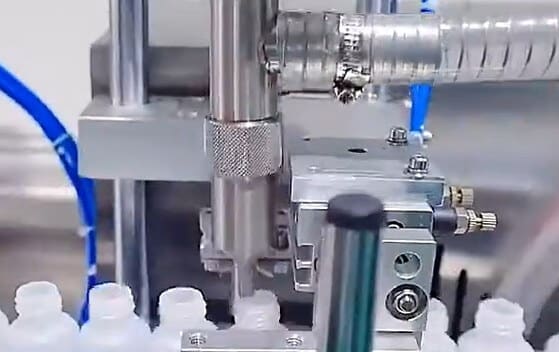

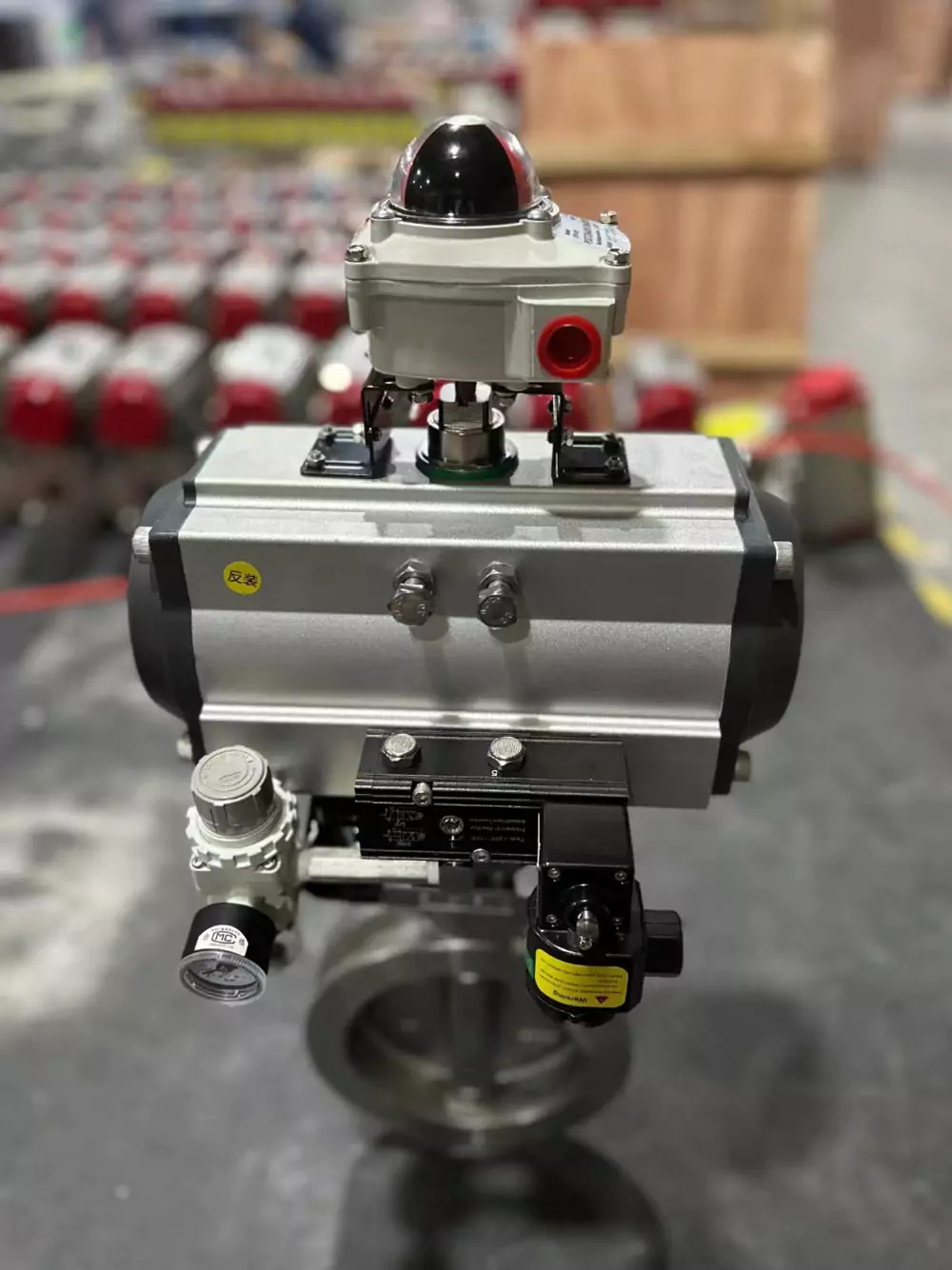

The design of liquid filling production line needs to be designed according to the actual production process and equipped with different working structures. The advantages of the filling machine production line are to provide high-performance, stable, and reliable filling production lines for the manufacturing industry and reduce material waste. Including the pneumatic fittings, pneumatic speed controller, PU tube, air cylinders.

Liquid filling production line

Liquid filling production is completed in several parts, and the content of production work completed at different stages is also different.

Therefore, the design of the liquid filling production line needs to be designed according to the actual production process and equipped with different working structures.

The advantage of the filling machine production line is to provide a high-performance, stable, and reliable filling production line for the manufacturing industry, reduces material waste, and saves mass production costs;

The program is controlled according to the production process, and the production efficiency is high; the environmental pollution in the production process is low.

Generally speaking, the filling production process of the liquid filling production line is divided into three stages, and the liquid filling machine is the main part of the entire liquid filling production line.

The main equipment for one-step filling is the blow molding machine, which is used for the preparation process before packaging,

The second stage is the main body, that is, the liquid filling machine, capping machine, capping machine, coding machine, labeling machine, etc.,

The final stage is mainly to pack and seal the boxes, and then store them in the warehouse. The main equipment includes familiar box sealing machines, palletizing,

Conveyor line and some testing equipment, there are more than ten kinds of equipment in the main link of the whole filling liquid filling machine production line, the output of this filling production line is very large,

Due to different products and different customer needs, automatic liquid filling production lines do not have standardized mechanical equipment and are usually customized according to customer needs.

The above is the introduction of the components of the liquid filling machine production line.