The pneumatic shut-off valve, pneumatic cut-off ball valve is a valve widely used in industrial fields, its function is to control the flow of medium through pneumatic force.

It has the characteristics of simple structure, convenient operation, and high reliability, and is widely used in petroleum, chemical, electric power, metallurgy, and other industries. Besides the pneumatic actuator, it has a manual wheel addon, under some failure conditions, the valve can be opened /closed manually for security reasons.

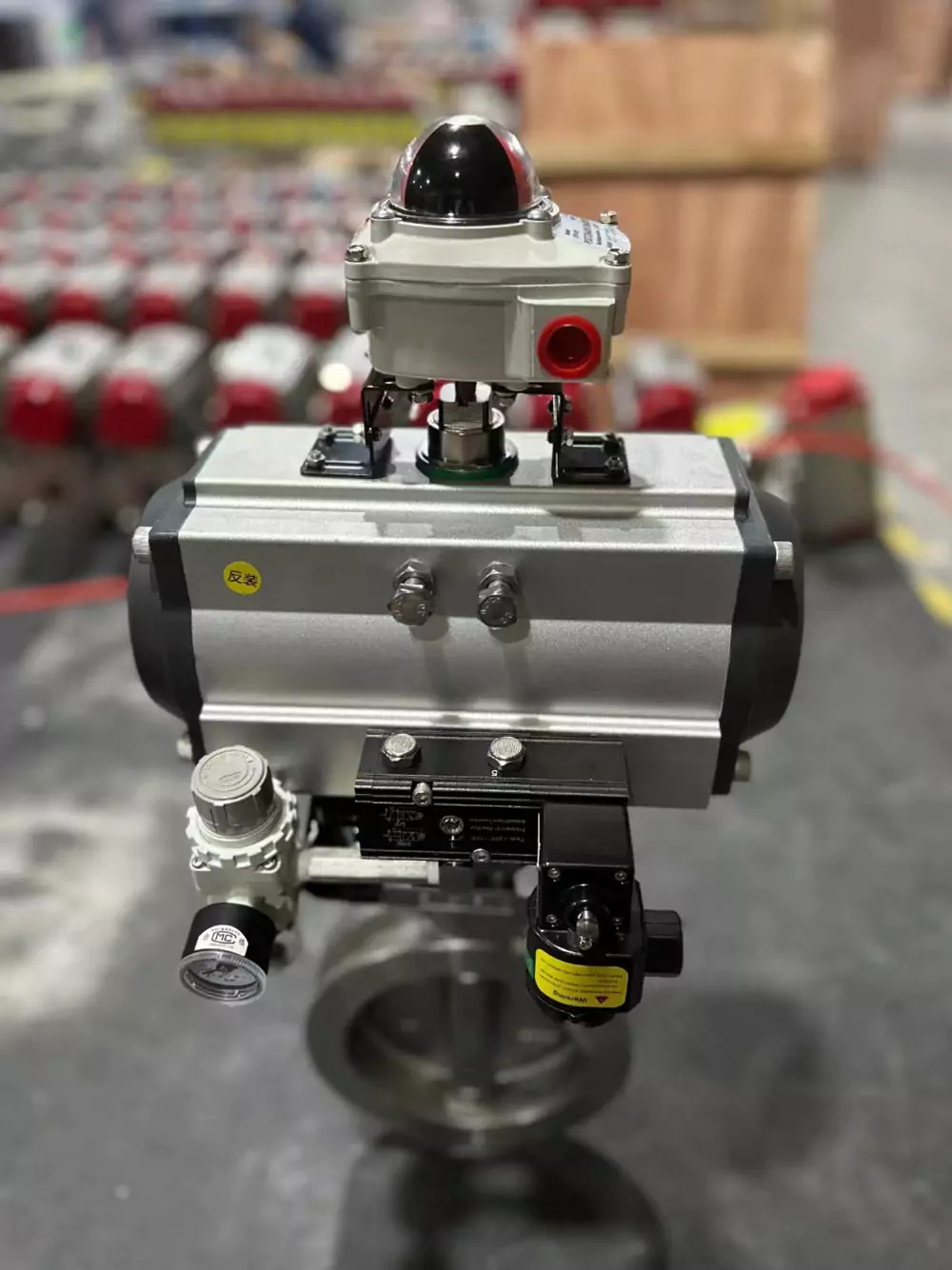

First of all, the structure of the pneumatic shut-off valve is simple, and it is composed of the valve body, valve cover, valve disc, and other components. The valve body and bonnet are usually made of cast iron or stainless steel for high strength and corrosion resistance. The valve ball or disc controls the flow of fluid through pneumatic force. When the pneumatic force acts on the valve ball or disc, the valve ball will close or open, thereby cutting off the fluid. This simple structure design makes the pneumatic shut-off valve have great advantages in installation and maintenance.

Secondly, the pneumatic cut-off valve is easy to operate. Since the pneumatic cut-off valve uses pneumatic force to control the opening and closing of the ball or disc, it is very convenient to operate. It only needs to control the opening and closing state of the ball or disc by controlling the adjustable pressure switch of the air source, without manual operation. This kind of operation not only improves work efficiency but also reduces the labor intensity of operators.

In addition, the pneumatic shut-off valve is usually equipped with a manual operation device, such as a manual wheel. When the compressed air source fails, the opening and closing of the valve ball or disc can be controlled by the manual operation device to ensure normal operation.

The most important thing is that the pneumatic shut-off valve has high reliability. Since the pneumatic cut-off valve uses pneumatic force to control the opening and closing of the disc, its action speed is fast and the response time is short. This quick-response feature enables the pneumatic shut-off valve to quickly cut off the fluid in an emergency to protect the safety of equipment and personnel.

In addition, the pneumatic shut-off valve has good sealing performance and can effectively prevent the leakage of the medium. This reliable performance makes pneumatic shut-off valves widely used in industrial production.

To sum up, as a valve widely used in the industrial field, the pneumatic shut-off cut-off valve has the characteristics of a simple structure, convenient operation, and high reliability. Its design makes installation and maintenance very easy, and it is very simple to operate. Moreover, its quick response and good sealing performance enable it to quickly cut off the fluid in an emergency to protect the safety of equipment and workers.

Therefore, pneumatic shut-off valves have been widely used in petroleum, chemical, electric power, metallurgy, and other industries, and have become indispensable and important equipment in industrial production.