Solenoid Valve Introduction and Types

With the advancement of fluid automation design technology, solenoid valves, as one of the control components, are finding increasing applications in a wide range of fields, with growing demands. These fields include fire protection, building automation, fine chemicals, water treatment, and biopharmaceuticals, among others. Solenoid valves are playing an increasingly important role in many sectors, indirectly improving our lives. A brief overview of their selection and application is provided below:

Solenoid Valve Structure, Principles, and Series Codes

According to the reference standard JB/T7352-2010 “Solenoid Valves for Industrial Process Control Systems,” the structural principles and corresponding series codes are divided into six major series: Z, M, H, D, P, and Y.

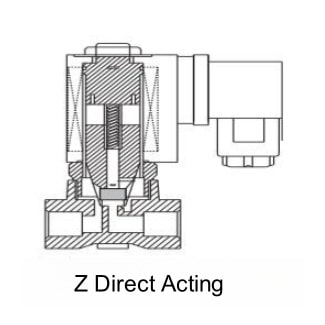

1. Direct Lift Type (Series Z)

Code: Z

Principle: This valve uses direct shut-off and pressure relief design, available in normally closed and normally open types. The normally closed type remains closed by default. When the coil is energized, electromagnetic force overcomes the spring force, and the moving core is attracted to the fixed core, opening the valve directly and allowing the medium to flow. When the coil is de-energized, the electromagnetic force disappears, and the moving core is reset by the spring force, closing the valve and stopping the medium. This direct lift design ensures reliable operation even with zero pressure difference and low vacuum conditions. The normally open type works in the opposite manner.

Example: Z Direct Acting Valve

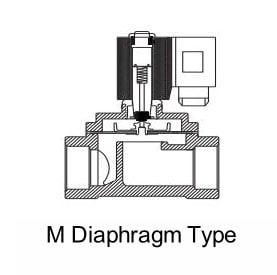

2. Diaphragm Type (Series M)

Code: M

Principle: This valve utilizes diaphragm movement to seal the chamber and relieve pressure. It is also available in normally closed and normally open types. In the normally closed type, the coil generates electromagnetic force, causing the moving core to attract the fixed core. As the moving core moves upward, a small valve port on the diaphragm is opened, relieving pressure. Simultaneously, the intermediate spring pulls the diaphragm upwards, opening the main valve and allowing the medium to flow. When the coil is de-energized, the electromagnetic force disappears, and the moving core is reset by the spring and medium pressure, closing the main valve, stopping the flow. This diaphragm lift structure can start with zero pressure difference. The normally open type operates in the reverse manner.

Example: M Diaphragm Type Valve

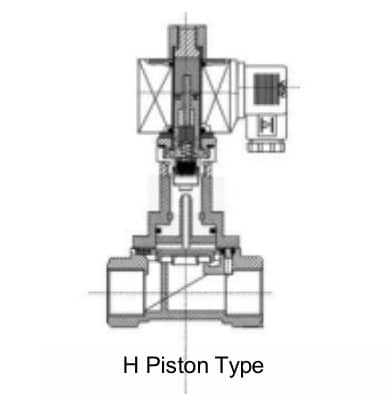

3. Piston Type (Series H)

Code: H

Principle: This valve uses piston movement to seal the chamber and relieve pressure. It is available in normally closed and normally open types. In the normally closed type, the coil generates electromagnetic force, causing the moving core to attract the fixed core. As the moving core moves upward, a small valve port on the piston is opened, relieving pressure. The intermediate spring pulls the piston upwards, opening the main valve and allowing the medium to flow. When the coil is de-energized, the electromagnetic force disappears, and the moving core is reset by the spring and medium pressure, closing the main valve and stopping the flow. This piston lift structure can also start with zero pressure difference. The normally open type operates in the reverse manner.

Example: H Piston Type Valve

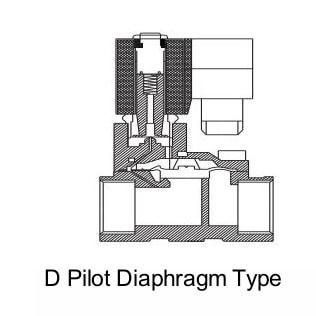

4. Pilot Diaphragm Type (Series D)

Code: D

Principle: This valve uses pilot diaphragm pressure relief to open the main valve. It is available in normally closed and normally open types. In the normally closed type, when the coil is energized, electromagnetic force attracts the moving and fixed cores, opening the pilot chamber. This opens the pressure relief on the diaphragm, causing the diaphragm to move upward, thus opening the main valve and allowing the medium to flow. When the coil is de-energized, the electromagnetic force disappears, and the moving core closes the pilot valve, allowing medium to flow into the balance hole. This increases the pressure in the upper chamber of the diaphragm and, under the action of the spring force, closes the main valve.

Example: D Pilot Diaphragm Type Valve

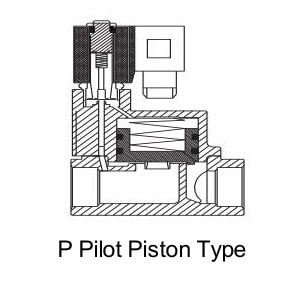

5. Pilot Piston Type (Series P)

Code: P

Principle: This valve is a combination of a pilot valve and main valve piston, using a pilot valve to open the main valve. In the normally closed type, when the coil is energized, electromagnetic force opens the pilot valve, allowing the medium to flow. The pressure in the upper chamber of the main valve piston decreases, creating a pressure differential that overcomes the spring resistance and causes the piston to move upward, opening the main valve and allowing the medium to flow. When the coil is de-energized, the electromagnetic force disappears, and the moving core resets, closing the pilot valve. The medium flows into the balance hole, increasing the pressure in the upper chamber of the piston and causing it to close under the spring force.

Example: P Pilot Piston Type Valve

This structure and principle overview provides insights into the different types of solenoid valves and their working mechanisms, enabling proper selection and application in various industries.

But, how to find the proper solenoid valve? Find more