The stainless steel pneumatic knife gate valve is an important industrial valve. The following is a detailed introduction to it:

I. Definition and Application

A stainless steel pneumatic knife gate valve uses a pneumatic actuator to control the valve’s opening and closing. It is primarily used to control the flow or conveying volume of powders, granular materials, pellets, and small pieces of material, and is widely used in industries such as metallurgy, mining, building materials, grain, and chemicals.

II. Structure and Operating Principle

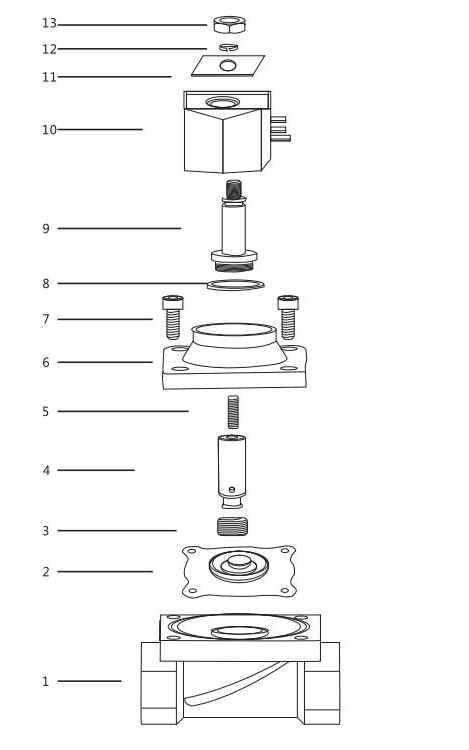

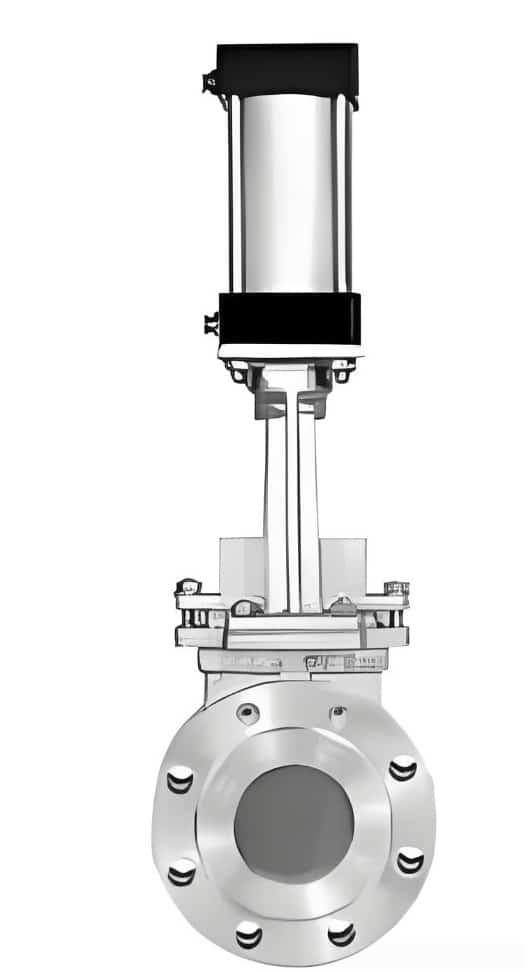

Structure: A pneumatic knife gate valve consists of two parts: the upper part houses the pneumatic actuator, and the lower part houses the valve. The opening and closing element is a gate disc, which moves perpendicular to the flow direction.

Operating Principle: Pneumatic knife gate valves can be equipped with accessories such as solenoid valves and proximity switches to achieve dual-position control and signal output, or they can be automatically controlled for continuous operation. When the pneumatic actuator receives a signal, it drives the gate disc up and down, thereby opening and closing the valve.

III. Features and Advantages

Simple and Compact Structure: The valve features a rational design, compact structure, and reliable sealing.

Easy and Flexible Operation: Compact and lightweight, easy to install and disassemble, and simple to operate.

Smooth Flow: Low flow resistance, suitable for flow control of various powders, granular materials, pellets, and small pieces.

Shearing Function: The gate has a shearing function that scrapes away sticking matter from the sealing surface and automatically removes debris.

Corrosion Resistance: Stainless steel prevents seal leakage caused by corrosion.

IV. Technical Parameters and Performance

Working Pressure: Typically between 0.6 MPa and 2.5 MPa.

Operating Temperature: Operates normally within the range of -20°C to 650°C (or -29°C to 180°C).

Material: Primarily stainless steel, with cast iron and carbon steel also available.

Size Range: Common sizes range from DN50 to DN600.

V. Usage Precautions

Media Requirements: While pneumatic knife gate valves can accommodate a wide range of media, their sealing performance may be compromised under extremely high or low pressure conditions.

Sealing Materials: After prolonged use, sealing materials such as rubber rings inside the cylinder may age, harden, and lose their elasticity, leading to air leaks. Regular inspection and replacement of the sealing materials is necessary.

Operating Force and Space: Due to the structural characteristics of knife gate valves, they require considerable force and space to open and close. This can be a limiting factor in certain confined or complex environments.

VI. Application Areas

Due to their unique advantages and wide range of applications, pneumatic knife gate valves are widely used in pulping, papermaking, coal pulverized ore slurry, and mud production processes, as well as in the papermaking, petrochemical, mining, drainage, and food industries. In these areas, pneumatic knife gate valves can effectively control fluid flow or delivery volume to meet various process requirements.

In summary, stainless steel pneumatic knife gate valves are industrial valves with superior performance, compact structure, and easy operation. When using them, it is important to select the appropriate model and specifications based on the actual operating conditions and media characteristics, and strictly follow operating procedures for installation, commissioning, and maintenance.