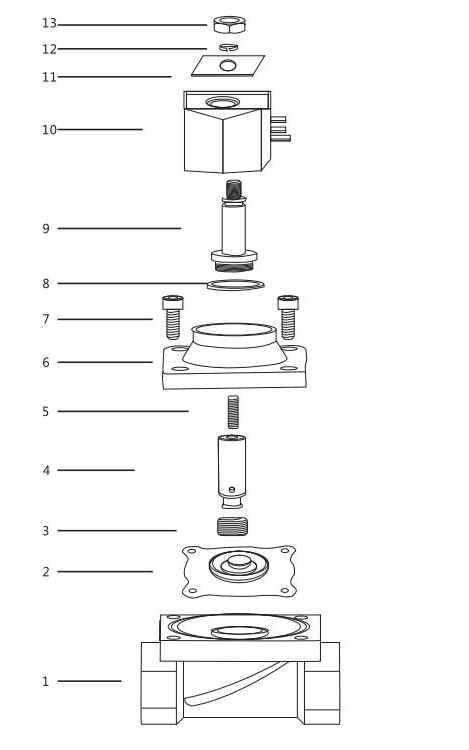

Pneumatic vibrator uses high-pressure gas discharged from an air compressor to connect to the product air inlet through a gas pipe. When the gas pushes the piston upward, the gas in the upper gas chamber of the piston is squeezed, and the squeezed gas is discharged through the exhaust hole. When the piston reaches the end point, the gas passes through the groove and the air passage to automatically switch the ventilation direction, so that the gas enters the upper air chamber of the piston. The high-pressure gas pushes the piston down to the end. The first cycle ends, and the second cycle begins. The continuous reciprocating cycle makes the vibrator produce translation and shaking, thereby generating vibration force.

Pneumatic vibrators are widely used in powder processing industries such as food, medicine, chemicals, pesticides, feed, ceramics, glass, cement, fuel, etc., suitable for fatigue test of parts or structural parts; hopper shaking and compaction; linearity and bowl Type feeder, sieve and strainer; vibrating table and mixing equipment.

Its main advantages and uses such as:

1. Only compressed air is needed as the power source, and the air consumption is small, which is safe and energy-saving. It is an ideal device for use in freezing or high-temperature environments, and is suitable for humid, dry, dusty or explosive environments.

2. Small size, few failures, easy installation and maintenance.

3. Quick stop or start, suitable for manual or automatic systems.

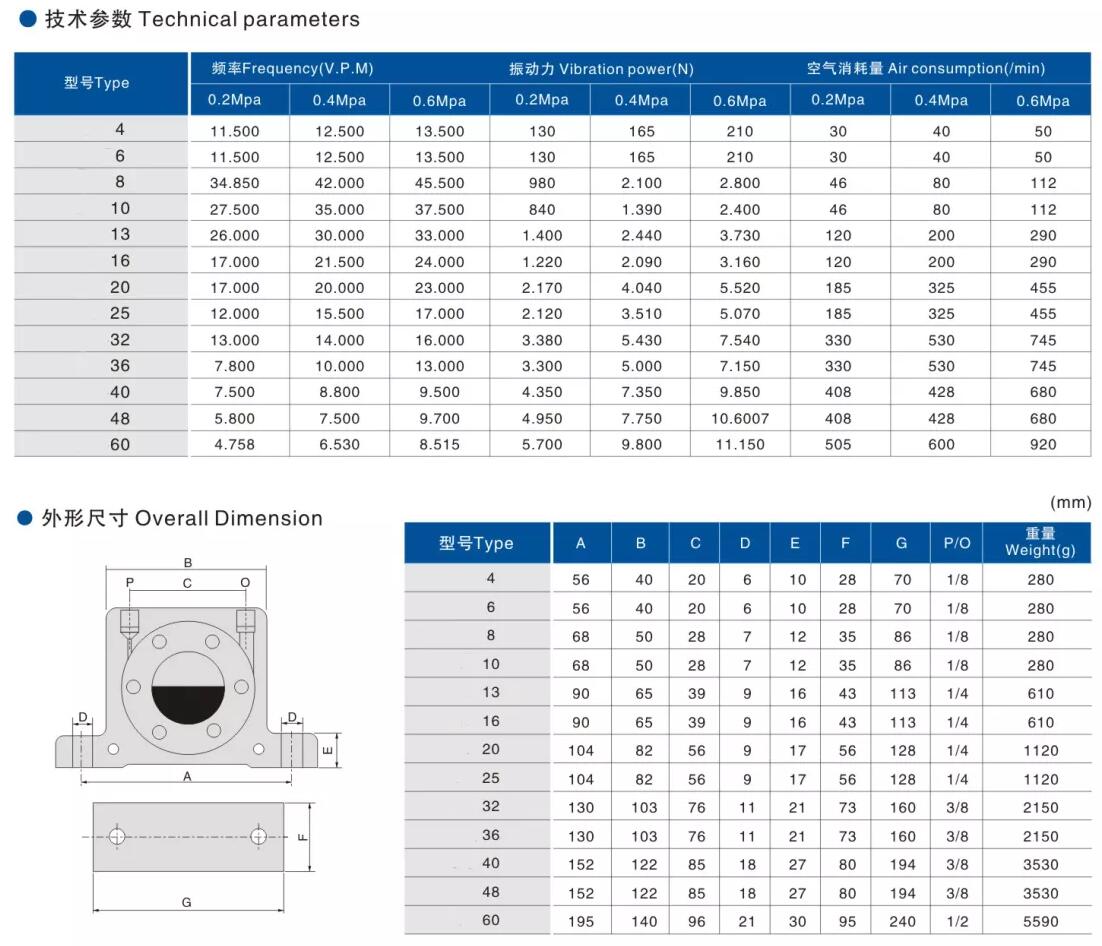

4. Vibration force, vibration frequency and amplitude can be adjusted by adjusting air pressure and flow during exercise.

5. A wide range of applications, suitable for fatigue testing of parts or structural parts; shaking and compaction of hoppers; linear and bowl feeders, screens and strainers; vibration tables and mixing equipment.

6. The service life of most types of pneumatic vibrators is relatively low.