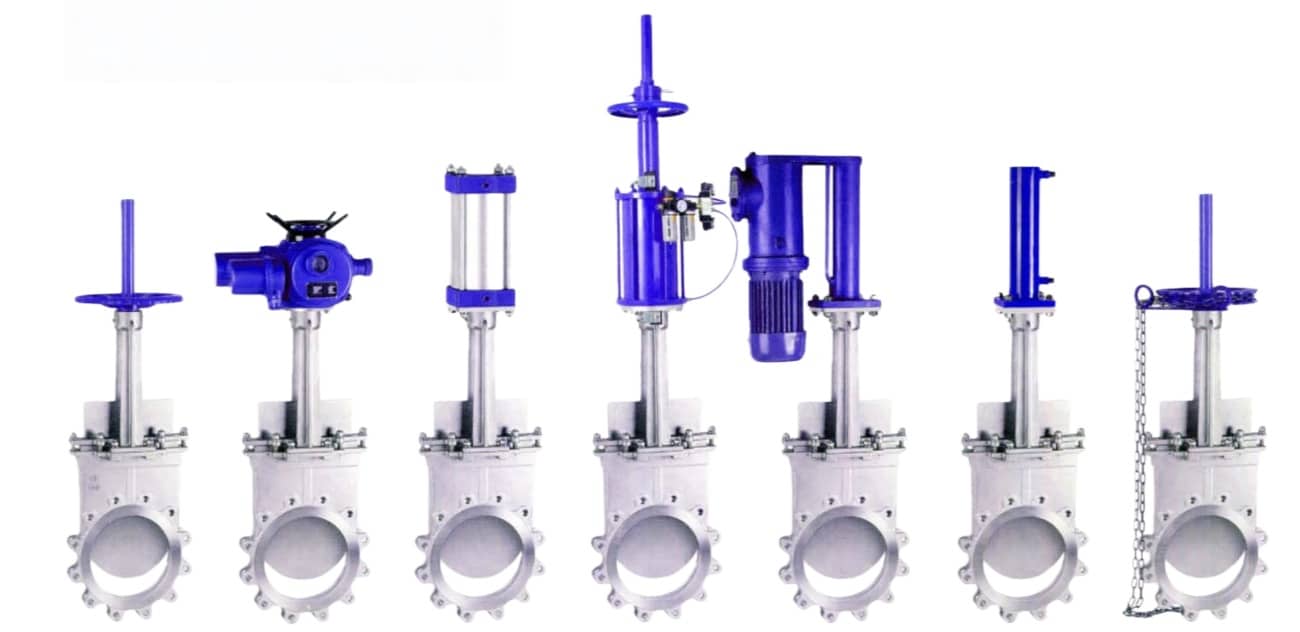

Pneumatic Slide Knife Gate Valve

Discover our advanced Pneumatic Knife Gate Valve, engineered for superior performance in demanding automated systems. This valve features a robust, fully enclosed design with a square or rectangular body, setting it apart from standard models. While maintaining structural similarity and accessory compatibility with standard knife gate valves, this model provides complete environmental isolation and a high-integrity seal, making it an ideal solution for applications with high environmental standards and frequent cycling. Its design also makes it a perfect heavy-duty Pneumatic Slide Gate Valve.

Key Features

- Fully Enclosed, Zero-Leakage Design: The gate is completely buried within the inner valve cavity, fully isolated from the external environment. A round packing bucket on the valve cover effectively prevents any leakage of the fluid medium.

- Dynamic Lateral-Press Sealing: The upper part of the gate and the bottom of the valve body are equipped with a unique gate-pressing device. This mechanism converts the vertical thrust of the valve stem into a powerful lateral force, ensuring the gate closes tightly against the valve seat to form a highly effective, reliable seal.

- Structural & Design Specifications:

- Valve Body: Square or Rectangular

- Connection: Square Flange Connection

- Sealing: Outer Rod Seal Series

- Compatibility: The drive device, detectors, and accessories are the same as those used for standard knife gate valves, ensuring easy integration and maintenance.

Technical Parameters

| Nominal diameter | DN50-1200 2″-48″ | |

|---|---|---|

| Pressure Level | 0.6MPa,1.0MPa,1.6MPa,2.5MPa | |

| ASME CLASS150 |

DN50~250 10Bar DN300~400 6Bar DN450 5Bar DN500~600 4Bar DN700~1200 2Bar |

|

| Proper Temperature | -20℃~+170℃ | |

| Leakage level | Zero leakage | |

Ideal Applications

This Pneumatic Knife Gate Valve is especially suitable for automatic control systems in industrial sectors that require frequent opening and closing cycles and have high environmental protection requirements.

- Food & Brewing

- Coal Liquefaction

- Sewage Treatment

- Chemical Industry

- Steel Manufacturing

- Other industrial sectors with high-frequency automation.

Product Features

Two-Way Sealing & Zero Leakage

The one-piece knife gate valve is designed with bi-directional sealing and ensures zero leakage. It can withstand high pressure differences and maintain full bore flow, achieving maximum flow capacity under demanding conditions.

Non-Groove Valve Seat Design

The smooth valve seat without grooves prevents medium accumulation on the sealing surface, effectively avoiding leakage or gate jamming caused by material build-up.

Precision Casting Valve Body

The valve body adopts an integral precision casting structure, providing superior strength, durability, and dimensional accuracy.

Elastic U-Shaped Valve Seat

The U-shaped elastic valve seat is embedded in the valve body to match the gate plate perfectly. The gate plate moves up and down with low friction, greatly extending the service life of the valve seat while maintaining two-way sealing performance.

Reliable O-Ring Sealing

A rubber O-ring is embedded in the flange groove, ensuring an easy and secure connection between the valve and pipeline with high sealing reliability.

Wide Application Range

This series of knife gate valves is widely applied in:

-

Urban sewage treatment

-

Pulp and paper industry

-

Mining and slurry discharge systems