SK Pneumatic Percussion Air Knocker Air Hammer

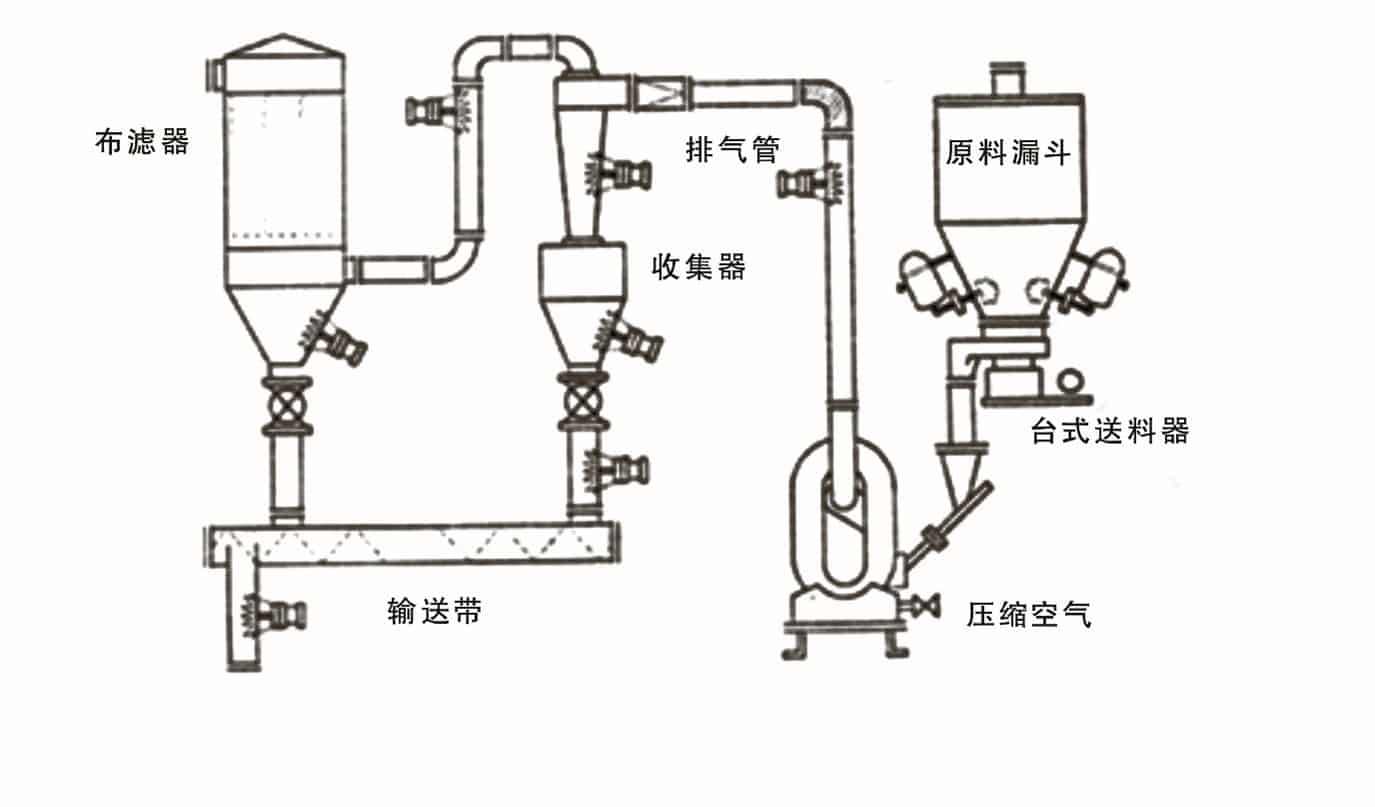

SK series pneumatic percussion hammer (automatic jar) is a new type of automatic percussion device independently developed by our company with the introduction of advanced foreign technology. It can effectively prevent the adhesion, blockage and bridging of powder in pipelines, silos and hoppers, without causing damage or deformation to the wall of the equipment. The uniquely designed magnetic piston gives the air hammer greater impact force. The outer shell is made of high-quality cast aluminum alloy, and the control box can adjust the percussion interval and percussion time.

The main features of this product are: large magnetic impact and good powder falling effect; low gas consumption, low operating cost, and good energy saving effect; adjustable percussion interval; reliable quality and low failure rate; simple structure and easy disassembly; novel and unique appearance design; impact-resistant piston (explosion-proof can be customized). It is widely used in pesticides, medicines, chemicals, cement, dyes, pigments, food, electronics, building materials, minerals, environmental protection and other industries, and is a powerful auxiliary for powder processing production lines.

Features:

2. Low air consumption, low operating cost, and good energy saving effect

3. Adjustable percussion interval

4. Reliable quality and low failure rate

5. Simple structure and easy disassembly

6. Novel and unique appearance design, impact-resistant piston (explosion-proof can be customized)

7. Widely used in pesticides, medicines, chemicals, cement, dyes, pigments, food, electronics, building materials, minerals, environmental protection and other industries

Fluid Media: Air

Specifications

| Model | Pressure | Air Consumption | Impact | Weight |

|---|---|---|---|---|

| SK-30 | 3~7 Kgf/cm2 | 0.028 L/Cycle | ~0.75 Kgm/sec | 1.1 KGS |

| SK-40 | 3~7 Kgf/cm2 | 0.082 L/Cycle | ~2.2 Kgm/sec | 2.2 KGS |

| SK-60 | 3~7 Kgf/cm2 | 0.228 L/Cycle | ~7.4 Kgm/sec | 5.1 KGS |

| SK-80 | 4~5 Kgf/cm2 | 0.455 L/Cycle | ~16.4 Kgm/sec | 11.1 KGS |

| SK-100 | 5~7 Kgf/cm2 | 1.012 L/Cycle | ~30.0 Kgm/sec | 37.5 KGS |

| SK-30LP | 3~7 Kgf/cm2 | 0.028 L/Cycle | ~1.1 Kgm/sec | 1.2 KGS |

| SK-40LP | 3~7 Kgf/cm2 | 0.082 L/Cycle | ~3.3 Kgm/sec | 2.5 KGS |

| SK-60LP | 3~7 Kgf/cm2 | 0.228 L/Cycle | ~11.1 Kgm/sec | 5.7 KGS |

| SK-80LP | 4~5 Kgf/cm2 | 0.455 L/Cycle | ~24.6 Kgm/sec | 12 KGS |

| SK-100LP | 5~7 Kgf/cm2 | 1.012 L/Cycle | ~45.0 Kgm/sec | 36.4 KGS |

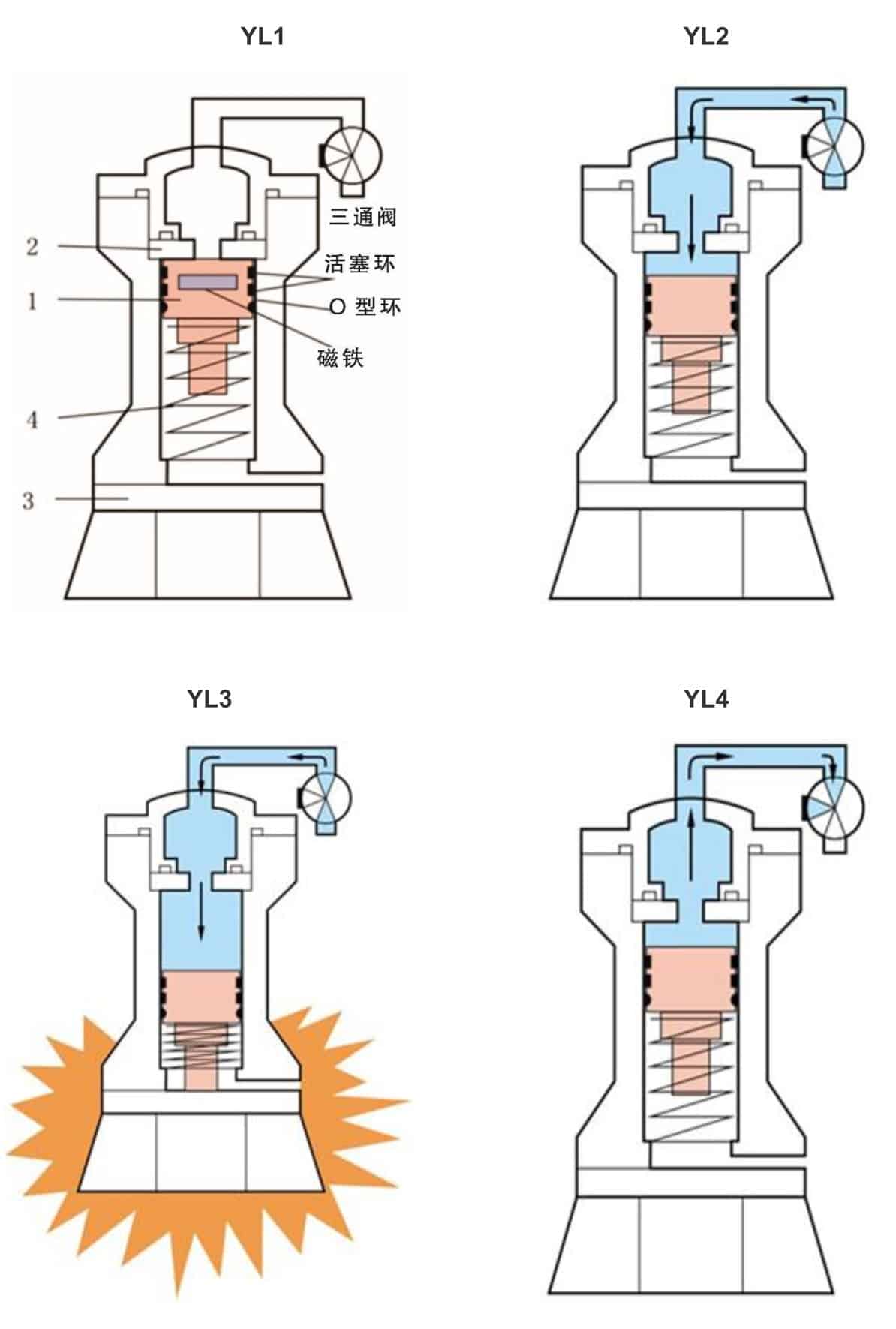

Working Principle:

When the pneumatic percussion hammer (automatic jar) is not supplied with compressed air (more than 3Kg/cm), the magnetic piston ① is fixed tightly on the base plate ② with the help of strong magnetic force. When the three-way solenoid valve is energized, compressed air flows into the air hammer body, and the pressure in the body increases. When it is greater than the magnetic force, the magnetic piston ① quickly separates from the base plate ②, and a strong counterattack force is generated due to the reaction force of the strong magnetic force. The magnetic piston falls at high speed and hits the base plate, and its impact force is transmitted to the silo, and the attached dust is knocked off with a strong impact force. When the three-way solenoid valve stops being energized, the compressed air in the air hammer body is discharged through the three-way solenoid valve, so the magnetic piston ① is slowly raised and then close to the base plate ② with the help of the return spring ④, and is closely connected to the base plate to return to the initial state through the magnetic force. In this way, one impact stroke is completed. By adjusting the air hammer controller in the electrical control box, the knocking interval and knocking time can be reduced or increased.

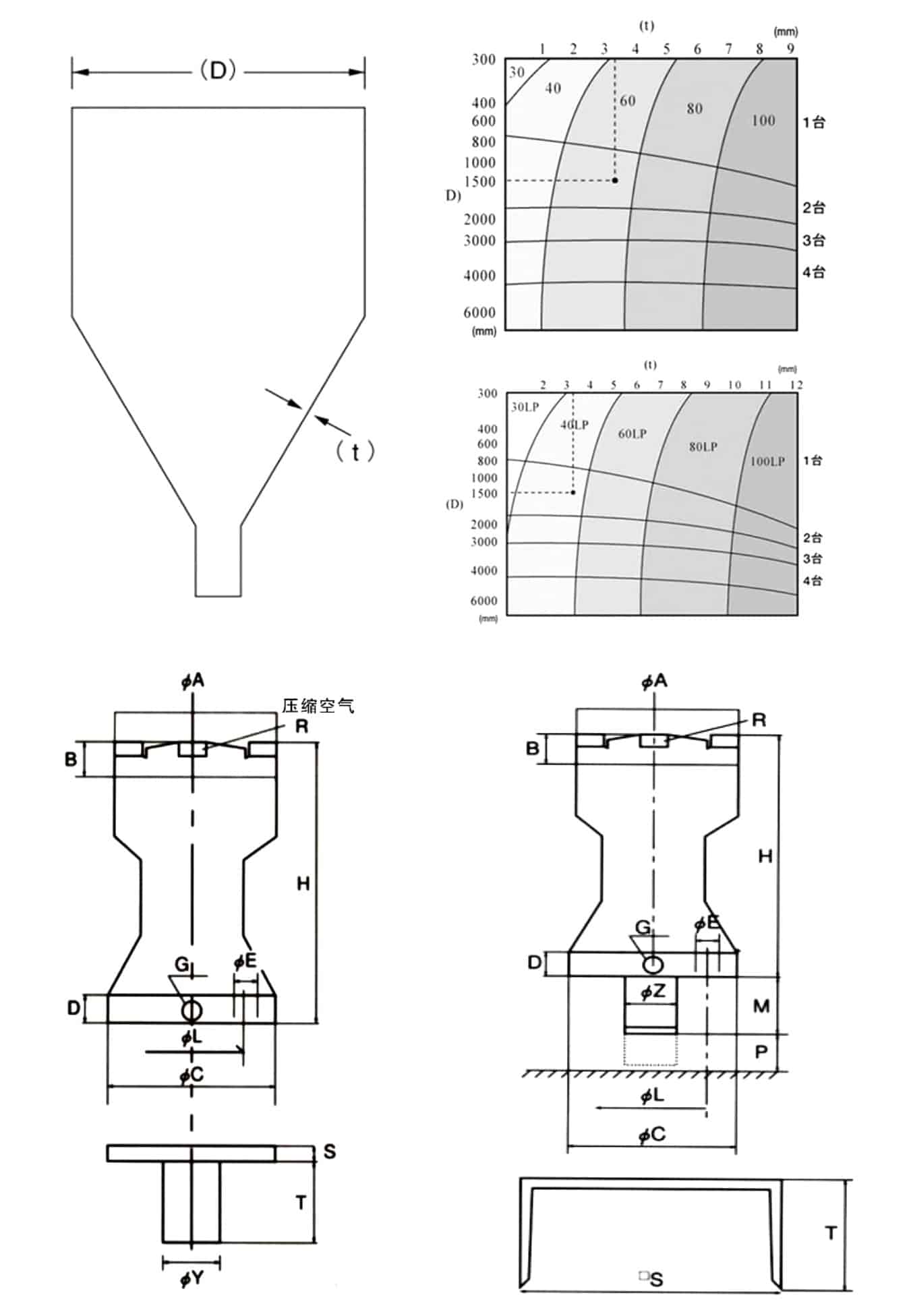

Selection:

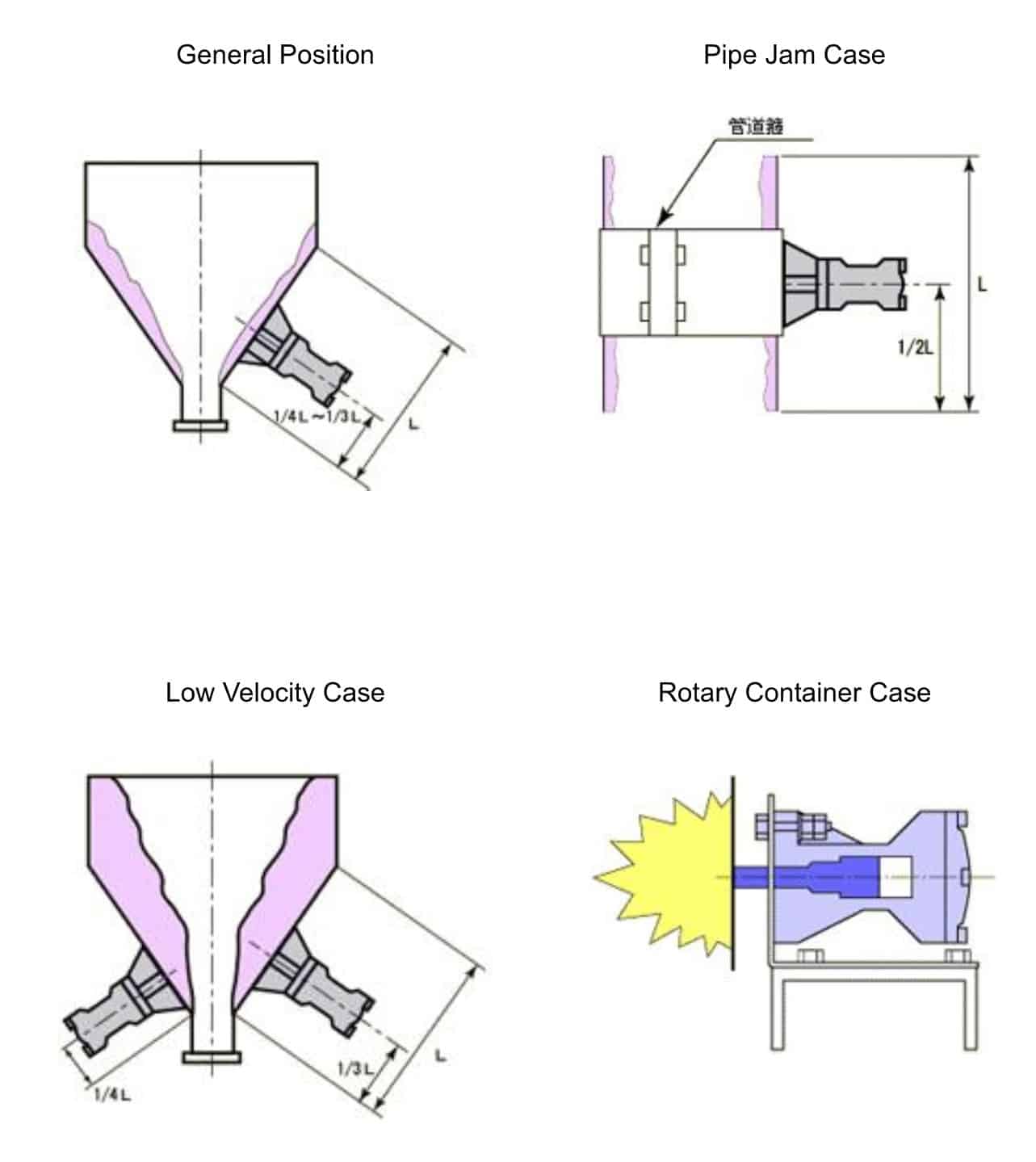

The selection of pneumatic hammer (automatic jar) is shown in the figure. The 60-degree conical hopper is roughly used as the reference. According to the diameter (D) and the thickness (t) of the conical part, the model and number of pneumatic hammers are selected from the figure. For example, if the hopper diameter (D) is 1500mm and the plate thickness (t) is 3mm, the 60-type is selected and the number is 2. And sometimes there are slight differences due to the shape of the hopper (pyramid, cone) and the physical properties and state of the powder in it.

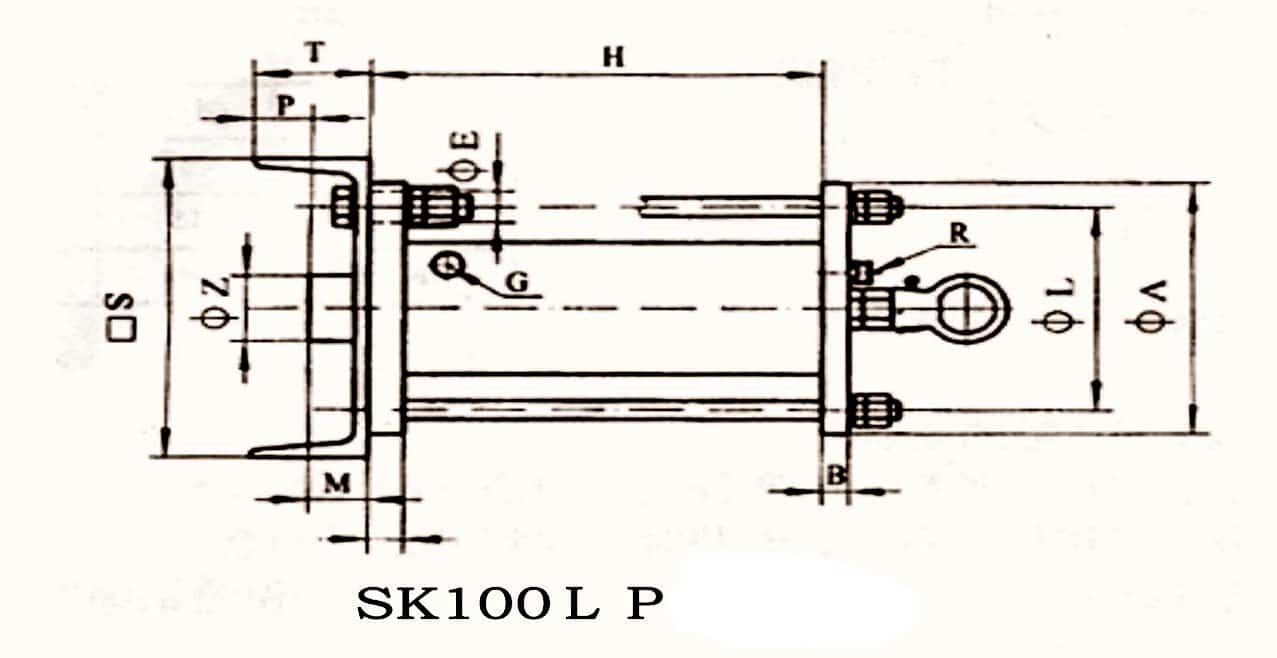

| Model | A | B | C | D | E | G | H | L | S | T | Y | R |

| SK-30 | 75 | 10 | 82 | 13 | 9 | 1/8 | 132 | 68 | 6 | 50 | 27 | 1/4 |

| SK-40 | 90 | 12 | 97 | 18 | 11 | 1/4 | 162 | 78 | 10 | 60 | 34 | 1/4 |

| SK-60 | 121 | 13 | 143 | 19 | 15 | 1/4 | 215 | 110 | 10 | 60 | 48 | 1/4 |

| SK-80 | 160 | 17 | 170 | 20 | 17 | 3/8 | 260 | 140 | 14 | 90 | 70 | 3/8 |

| Model | A | B | C | D | E | G | H | L | S | T | R | Z | M | P |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SK-30LP | 75 | 10 | 82 | 13 | 9 | 1/8" | 132 | 68 | 100 | 50 | 1/4" | 20 | 25 | 25 |

| SK-40LP | 90 | 22 | 97 | 18 | 11 | 1/4" | 162 | 78 | 150 | 60 | 1/4" | 25 | 25 | 35 |

| SK-60LP | 121 | 13 | 143 | 19 | 15 | 1/4" | 215 | 110 | 200 | 60 | 1/4" | 40 | 25 | 35 |

| SK-80LP | 160 | 17 | 170 | 20 | 17 | 3/8" | 260 | 140 | 200 | 60 | 3/8" | 50 | 25 | 35 |

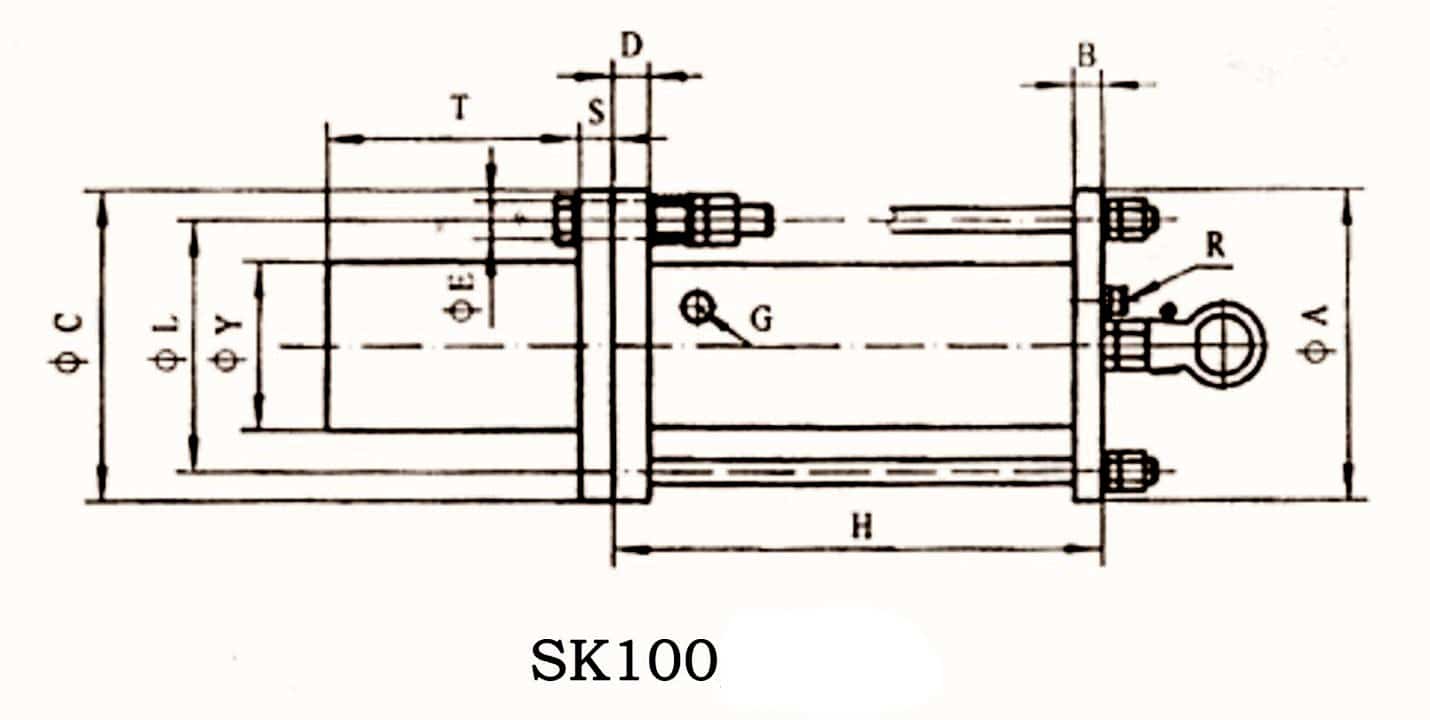

| Model | A | B | C | D | E | G | H | L | S | T | Y | R |

| SK-100 | 200 | 18 | 200 | 23 | 17 | 3/8" | 318 | 160 | 18 | 90 | 70 | 3/8" |

| Model | A | B | C | D | E | G | H | L | S | T | R | Z | M | P |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SK-100LP | 200 | 18 | 200 | 3 | 17 | 3/8"" | 318 | 160 | 200 | 60 | 3/8"" | 50 | 15 | 45 |

Installation:

Notes:

1. The air source must be clean, because polluted air will accelerate the wear of the piston seal, causing the seal to fail, and also have a great impact on the life of the two-position three-way electromagnetic reversing valve.

2. The air hammer seat and the warehouse wall must be welded firmly, and the connection between the air hammer and the air hammer seat must be tightened, otherwise after a period of knocking, there will be looseness and fall off. It is necessary to check whether the air hammer is installed firmly.

3. The adjustment of the air hammer controller varies due to different air hammer models and installation conditions. If you are not clear about the problem, please consult our company.

4. When welding the air hammer seat, if the warehouse wall is too thin, please consider adding a reinforcement plate between the air hammer seat and the warehouse wall.

5. After two months of safe use of this product, it is recommended to disassemble and add grease to increase the service life.