ALB Series Stainless Steel Low Temperature Cryogenic Solenoid Valve

ALB Series 2/2-way normally closed cryogenic solenoid valve is designed for precise control of cryogenic fluids such as liquid oxygen, liquid nitrogen, and liquid carbon dioxide. Constructed from durable SS316 stainless steel with PTFE sealing, it ensures excellent corrosion resistance and reliability under extreme low temperatures down to -196°C. The valve remains closed when de-energized and opens when energized, providing stable operation with a working pressure up to 80 bar. Recommended installation is with the solenoid positioned vertically upright for optimal performance.

-

Fluid Temperature: -196°C ~ +110°C

-

Ambient Temperature: -20°C ~ +65°C

-

Voltage: AC220V / DC24V

-

Body Material: SS316 Stainless Steel

-

Seal Material: PTFE

-

Orifice Size: 2.0–6.0 mm

-

Pipe Size: 1/8” ~ 1/2”

-

Working Pressure: 0–80 Bar

Features:

-

Applicable Fluids: Liquid oxygen, liquid nitrogen, liquid carbon dioxide, and other non-corrosive cryogenic liquids

-

Installation Direction: Flow follows the arrow; best installed with the solenoid vertically upright

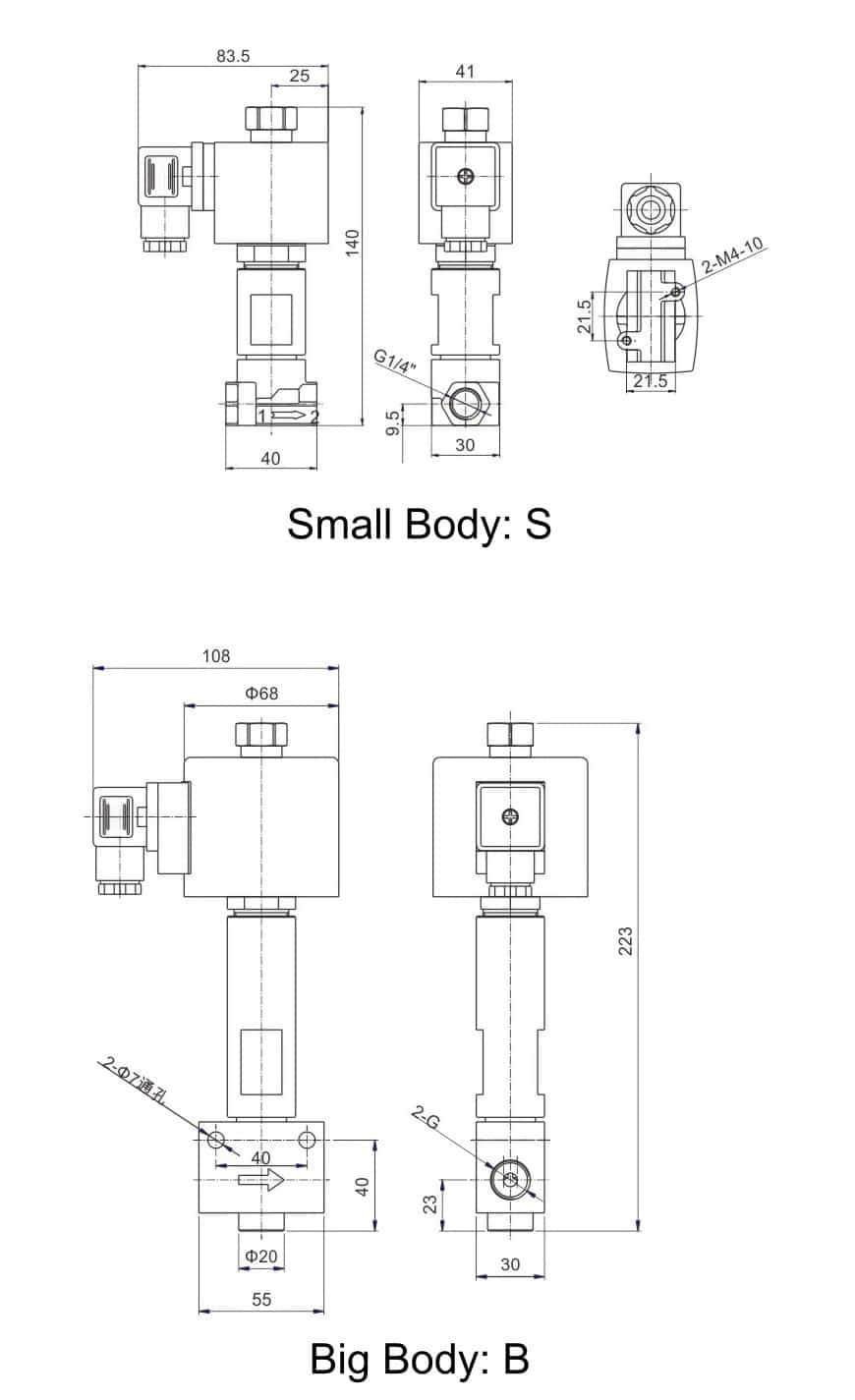

Dimensions

How to order

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|

| Series | Port Size | Voltage | Seal Material | Orifice (mm) |

Body Material | Operation | Coil Type | Thread Standard |

| ALB | 15 | U2 | N | 15L | B | C | D | N |

| 06: 1/8″ 08: 1/4″ 10: 3/8″ 15: 1/2″ 20: 3/4″ 25: 1″ 35: 1-1/4″ 40: 1-1/2″ 50: 2″ |

U1: 110VAC U2: 220VAC U3: 380VAC U4: 24V DC U5: 12V DC U6: 36V AC U7: 24V AC |

N: NBR V: VITON E: EPDM T: PTFE |

1L: 1.0 2L: 2.0 3L: 3.0 4L: 4.0 … 10L: 10 15L: 15 … 50L: 50 |

B: Brass S1: SS316 S2: SS304 NY: Nylon UP: UPVC |

C: Normally Closed

O: Normally Open |

D: DIN Standard

W: Lead Wire X: EX-Proof A: Water-Proof |

B: BSP

G: G N: NPT |

Technical Data Sheet

| Thread | Orifice (mm) |

CV Factor |

Pressure differential(Bar) | Power | Min. Temp. ℃ |

Max. Temp. ℃ |

Valve Body Size | Weight (KG) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | VA | W | ||||||||||||

| Liquid oxygen Liquid nitrogen |

Water Hot water Lliquid |

Light oil ≤20CST |

AC 220V |

DC 24V |

|||||||||||

| AC | DC | AC | DC | AC | DC | ||||||||||

| 1/8″ | 2.0 | 0.14 | 0 | 40 | 35 | 40 | 35 | 35 | 25 | 18 | 17 | -196 | 110 | S | 0.7 |

| 2.5 | 0.23 | 0 | 30 | 25 | 30 | 25 | 25 | 20 | 18 | 17 | -196 | 110 | S | 0.7 | |

| 3.0 | 0.30 | 0 | 25 | 20 | 25 | 20 | 20 | 16 | 18 | 17 | -196 | 110 | S | 0.7 | |

| 4.0 | 0.60 | 0 | 10 | 8 | 10 | 8 | 10 | 8 | 18 | 17 | -196 | 110 | S | 0.7 | |

| 5.0 | 0.65 | 0 | 5 | 3 | 5 | 3 | 4 | 2.5 | 18 | 17 | -196 | 110 | S | 0.7 | |

| 6.0 | 0.80 | 0 | 3 | 2 | 3 | 2 | 2 | 2 | 18 | 17 | -196 | 110 | S | 0.7 | |

| 1/4″ | 2.0 | 0.14 | 0 | 40 | 35 | 40 | 35 | 35 | 25 | 18 | 17 | -196 | 110 | S | 0.7 |

| 2.0 | 0.14 | 0 | 80 | 60 | 80 | 60 | 70 | 50 | 50 | 40 | -196 | 110 | B | 2.2 | |

| 2.0 | 0.14 | 0 | 80 | 60 | 80 | 60 | 70 | 50 | 45 | 50 | -196 | 110 | B | 2.0 | |

| 2.5 | 0.23 | 0 | 30 | 25 | 30 | 25 | 25 | 20 | 18 | 17 | -196 | 110 | S | 0.7 | |

| 2.5 | 0.23 | 0 | 70 | 55 | 70 | 55 | 60 | 45 | 50 | 40 | -196 | 110 | B | 2.2 | |

| 2.5 | 0.23 | 0 | 70 | 55 | 70 | 55 | 60 | 45 | 45 | 50 | -196 | 110 | B | 2.0 | |

| 3.0 | 0.30 | 0 | 25 | 20 | 25 | 20 | 20 | 16 | 18 | 17 | -196 | 110 | S | 0.7 | |

| 3.0 | 0.30 | 0 | 60 | 50 | 60 | 50 | 50 | 40 | 50 | 40 | -196 | 110 | B | 2.2 | |

| 3.0 | 0.30 | 0 | 60 | 50 | 60 | 50 | 50 | 40 | 45 | 50 | -196 | 110 | B | 2.0 | |

| 4.0 | 0.60 | 0 | 10 | 8 | 10 | 8 | 10 | 8 | 18 | 17 | -196 | 110 | S | 0.7 | |

| 4.0 | 0.60 | 0 | 24 | 20 | 24 | 20 | 20 | 16 | 50 | 40 | -196 | 110 | B | 2.2 | |

| 4.0 | 0.60 | 0 | 24 | 20 | 24 | 20 | 20 | 16 | 45 | 50 | -196 | 110 | B | 2.0 | |

| 5.0 | 0.65 | 0 | 5 | 3 | 5 | 3 | 4 | 2.5 | 18 | 17 | -196 | 110 | S | 0.7 | |

| 5.0 | 0.65 | 0 | 12 | 8 | 12 | 8 | 10 | 6 | 50 | 40 | -196 | 110 | B | 2.2 | |

| 5.0 | 0.65 | 0 | 12 | 8 | 12 | 8 | 10 | 6 | 45 | 50 | -196 | 110 | B | 2.0 | |

| 6.0 | 0.80 | 0 | 3 | 2 | 3 | 2 | 2 | 2 | 18 | 17 | -196 | 110 | S | 0.7 | |

| 6.0 | 0.80 | 0 | 6 | 4 | 6 | 4 | 4 | 3 | 50 | 40 | -196 | 110 | B | 2.2 | |

| 6.0 | 0.80 | 0 | 6 | 4 | 6 | 4 | 4 | 3 | 45 | 50 | -196 | 110 | B | 2.0 | |

| 3/8″ | 2.0 | 0.3 | 0 | 80 | 60 | 80 | 60 | 70 | 50 | 50 | 40 | -196 | 110 | B | 2.1 |

| 2.0 | 0.3 | 0 | 80 | 60 | 80 | 60 | 70 | 50 | 45 | 50 | -196 | 110 | B | 1.9 | |

| 2.5 | 0.3 | 0 | 70 | 55 | 70 | 55 | 60 | 45 | 50 | 40 | -196 | 110 | B | 2.1 | |

| 2.5 | 0.3 | 0 | 70 | 55 | 70 | 55 | 60 | 45 | 45 | 50 | -196 | 110 | B | 1.9 | |

| 3.0 | 0.3 | 0 | 60 | 50 | 60 | 50 | 50 | 40 | 50 | 40 | -196 | 110 | B | 2.1 | |

| 3.0 | 0.3 | 0 | 60 | 50 | 60 | 50 | 50 | 40 | 45 | 50 | -196 | 110 | B | 1.9 | |

| 4.0 | 0.3 | 0 | 24 | 20 | 24 | 20 | 20 | 16 | 50 | 40 | -196 | 110 | B | 2.1 | |

| 4.0 | 0.3 | 0 | 24 | 20 | 24 | 20 | 20 | 16 | 45 | 50 | -196 | 110 | B | 1.9 | |

| 5.0 | 0.3 | 0 | 12 | 8 | 12 | 8 | 10 | 6 | 50 | 40 | -196 | 110 | B | 2.1 | |

| 5.0 | 0.3 | 0 | 12 | 8 | 12 | 8 | 10 | 6 | 45 | 50 | -196 | 110 | B | 1.9 | |

| 6.0 | 0.3 | 0 | 6 | 4 | 6 | 4 | 4 | 3 | 50 | 40 | -196 | 110 | B | 2.1 | |

| 6.0 | 0.3 | 0 | 6 | 4 | 6 | 4 | 4 | 3 | 45 | 50 | -196 | 110 | B | 1.9 | |

| 1/2″ | 2.0 | 0.3 | 0 | 80 | 60 | 80 | 60 | 70 | 50 | 50 | 40 | -196 | 110 | B | 2.0 |

| 2.0 | 0.3 | 0 | 80 | 60 | 80 | 60 | 70 | 50 | 45 | 50 | -196 | 110 | B | 1.8 | |

| 2.5 | 0.3 | 0 | 70 | 55 | 70 | 55 | 60 | 45 | 50 | 40 | -196 | 110 | B | 2.0 | |

| 2.5 | 0.3 | 0 | 70 | 55 | 70 | 55 | 60 | 45 | 45 | 50 | -196 | 110 | B | 1.8 | |

| 3.0 | 0.3 | 0 | 60 | 50 | 60 | 50 | 50 | 40 | 50 | 40 | -196 | 110 | B | 2.0 | |

| 3.0 | 0.3 | 0 | 60 | 50 | 60 | 50 | 50 | 40 | 45 | 50 | -196 | 110 | B | 1.8 | |

| 4.0 | 0.3 | 0 | 24 | 20 | 24 | 20 | 20 | 16 | 50 | 40 | -196 | 110 | B | 2.0 | |

| 4.0 | 0.3 | 0 | 24 | 20 | 24 | 20 | 20 | 16 | 45 | 50 | -196 | 110 | B | 1.8 | |

| 5.0 | 0.3 | 0 | 12 | 8 | 12 | 8 | 10 | 6 | 50 | 40 | -196 | 110 | B | 2.0 | |

| 5.0 | 0.3 | 0 | 12 | 8 | 12 | 8 | 10 | 6 | 45 | 50 | -196 | 110 | B | 1.8 | |

| 6.0 | 0.3 | 0 | 6 | 4 | 6 | 4 | 4 | 3 | 50 | 40 | -196 | 110 | B | 2.0 | |

| 6.0 | 0.3 | 0 | 6 | 4 | 6 | 4 | 4 | 3 | 45 | 50 | -196 | 110 | B | 1.8 | |