ZBSF Stainless Steel SS316 SS304 Flange Solenoid Valve

ZBSF all stainless steel solenoid valve – it can automatically open or close after receiving the electric control signal to realize the on-off or flow control of the liquid medium in the pipeline. ZBSF series all-stainless steel solenoid valve is an actuator used in industrial process automation control system. It can automatically open or close after receiving the electric control signal to realize the on-off or flow control of the liquid medium in the pipeline.

All-stainless steel solenoid valves can be widely used in production and scientific research departments such as textiles, printing, chemicals, plastics, rubber, pharmaceuticals, food, building materials, machinery, electrical appliances, surface treatment, as well as bathrooms, canteens, air conditioners and other daily life facilities. ZBSF-Y series solenoid valves are mainly used for the control of liquid media such as corrosive liquids, ultra-clean liquids and edible liquids. ZBSF series solenoid valves are mainly used for the control of gaseous media such as corrosive gases and ultra-clean gases.

Body material : SUS201,SUS304,SUS316(CF8M),SUS 304L(CF8),SUS 316L(CF3M),WCB,Brass,etc.

Full port : 1/4″-4″(DN8-DN100)

Working Pressure: PN10-16,1-16Mpa,10-16Bar

Medium Temperature : – 20 ℃ ~ + 180°C, Optional(- 20℃ ~ + 350°C)

Connection Type: Weld, Thread, Socket, Clamped, Flanged

Connection Standards : BSPT, Optional(NPT, BSP, BSPP)

Sealing: PTFE, RPTFE, PPL ETC

Diaphragm : NBR, Silicone, VITON, FKM, Fluororubber

Voltages : DC24V,AC220V

Control Mode: Normally Closed (Powered On), Normally Open (Powered Off)

Solenoid Coil Waterproof Level : IP-65 Option(IP-67, IP-68) Iron shell coil

Waterproof Level : IP-64 Option(IP-67, IP-68)

Explosion Proof: Option(Ex db IIC T4/T6 Gb: Ex tb IIIC T130℃/T80’℃ Db)

Body material: SS316 SS304

Pressure: 16 Bar, 1.6 MPa

Pipe size: 3/8″ – 4″

Fluid Media: Compressed air, Gas, Liquid, etc.

Model: ZBSF ZBSF-Y

| Item | Specifications | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Working Medium | Corrosive fluid,clean fluid,edible fluid ZBSF-1:Gas,ZBSF-1Y:Liquid ZBSF-2:Gas,ZBSF-1Y:Liquid |

|||||||||||

| Medium Temperture(℃) | ZBSF-1(1Y):≤60℃, ZBSF-2(2):≤280℃ | |||||||||||

| Operation Pressure(MPa) | 1.6 | |||||||||||

| Operation Pressure(MPa) | 0~1.6(less than 50mm) 0.05~1.6(more than 50mm) | |||||||||||

| Orifice Size(mm) | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 |

| Rated Flow Coefficient(KV) | AC220V specifications for special orders | |||||||||||

| Service Life | According to JB/T7352-94 regulations | |||||||||||

| Leakage Rate | According to JB/T7352-94-F regulations | |||||||||||

| Power Waste | AC≤70VA | |||||||||||

| Ex-Proof Mark | DIIBT4 | |||||||||||

| Ex-Proof Certificate Number | CE991010 | |||||||||||

| Outlet Connection | Internal thread M20×1.5 | |||||||||||

| Ambient Temperature | -40~+60℃ | |||||||||||

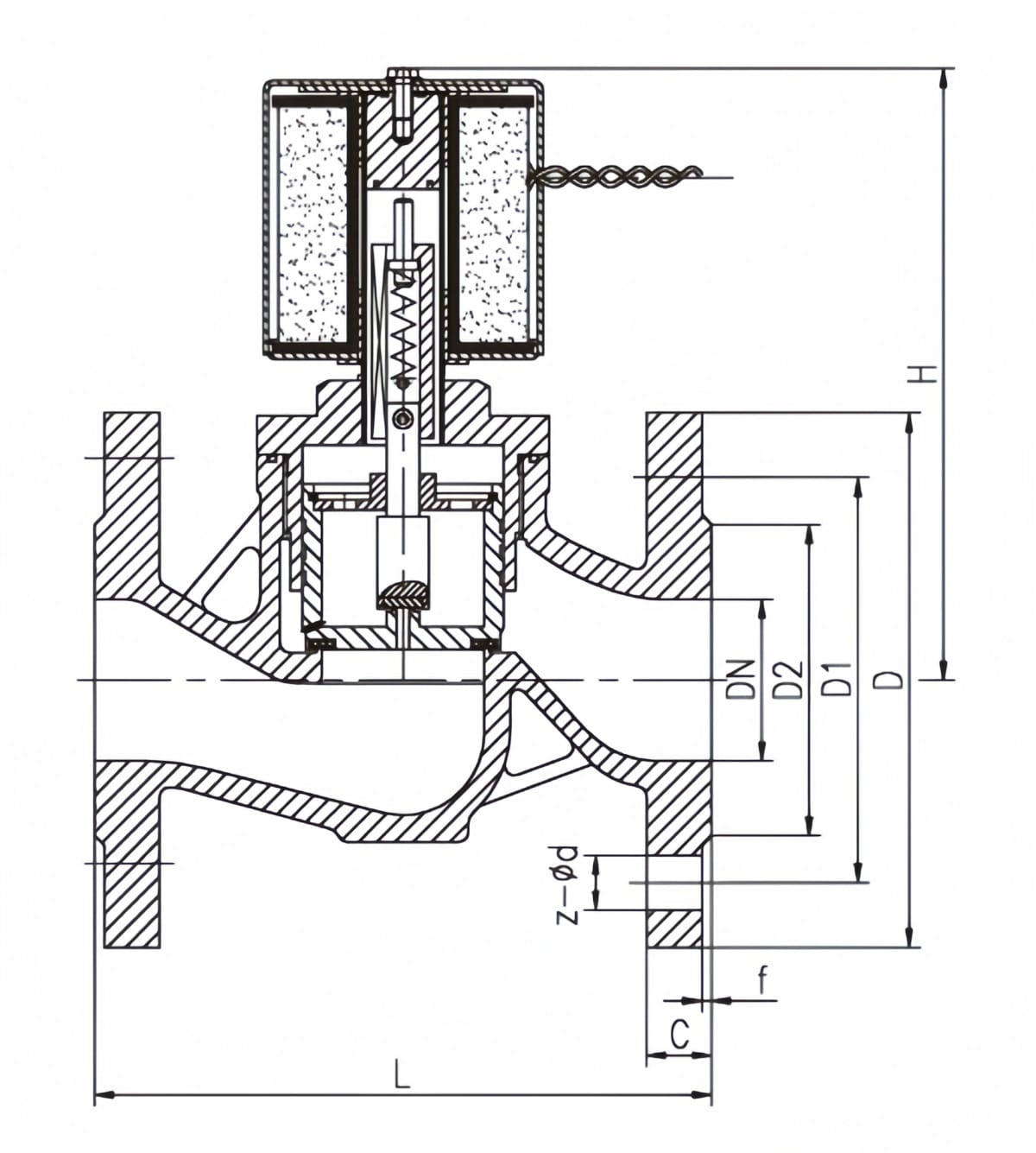

| DN | L | H | D | D1 | D2 | b | f | n-d |

|---|---|---|---|---|---|---|---|---|

| 10 | 115 | 148 | 90 | 60 | 41 | 14 | 2 | 4-14 |

| 15 | 115 | 148 | 95 | 65 | 46 | 14 | 2 | 4-14 |

| 20 | 115 | 148 | 105 | 75 | 56 | 16 | 2 | 4-14 |

| 25 | 125 | 148 | 115 | 85 | 65 | 16 | 3 | 4-14 |

| 32 | 150 | 182 | 140 | 100 | 76 | 18 | 3 | 4-18 |

| 40 | 165 | 182 | 150 | 110 | 84 | 18 | 3 | 4-18 |

| 50 | 190 | 192 | 160 | 125 | 99 | 20 | 3 | 4-18 |

| 65 | 290 | 265 | 185 | 145 | 118 | 20 | 3 | 8-18 |

| 80 | 310 | 276 | 200 | 160 | 132 | 20 | 3 | 8-18 |

| 100 | 350 | 373 | 220 | 185 | 156 | 22 | 3 | 8-18 |

| 125 | 400 | 416 | 250 | 210 | 184 | 22 | 3 | 8-18 |

| 150 | 480 | 440 | 285 | 240 | 211 | 24 | 3 | 8-22 |

- Corrosion resistance: Most parts are made of stainless steel or cast stainless steel with good corrosion resistance.

- Heat resistance: The electromagnetic parts and seals are all made of special high-temperature resistant electrical materials and sealing materials, and effective insulation measures are adopted.

- Wear-resistant: Reasonable material selection, the valve cup and guide sleeve cleverly use the lubrication of the fluid to reduce wear.

- Reliable: The structure is simple and compact, combining the advantages of direct-acting and pilot indirect solenoid valves, and can work reliably under low or zero pressure differential conditions.