Stainless Steel Vacuum Solenoid Valve

The VCA vacuum solenoid valve is a direct-acting stainless steel valve designed for vacuum pump systems and vacuum pipelines. With high sealing performance and reliable anti-backflow protection, it ensures safe and stable operation under vacuum conditions. This industrial-grade vacuum solenoid valve is widely applied in vacuum packaging, thermoforming, suction systems, metallurgy, and automated water supply control.

-

Nominal Diameter: DN3–DN200

-

Vacuum Pressure: 0.1 MPa

-

Medium Temperature: 0–100°C

-

Ambient Temperature: -10–+40°C

-

Body Material: Cast Steel, Stainless Steel

-

Applicable Media: Air, gases, oil, non-corrosive liquids

-

Actuation: Electromagnetic (direct-acting)

-

Connection Type: Flange, Thread, Welding

-

Control Mode: Normally Closed / Normally Open

-

Power Supply: Available in AC/DC, various voltages

-

Standards: GB, DIN, API, ANSI

-

Optional Features: Signal feedback, Explosion-proof design

Body material: SS316 SS304

Pipe size: 1/8″ – 2″

Fluid Media: Air, gases, oil, non-corrosive liquids

Model: VCA

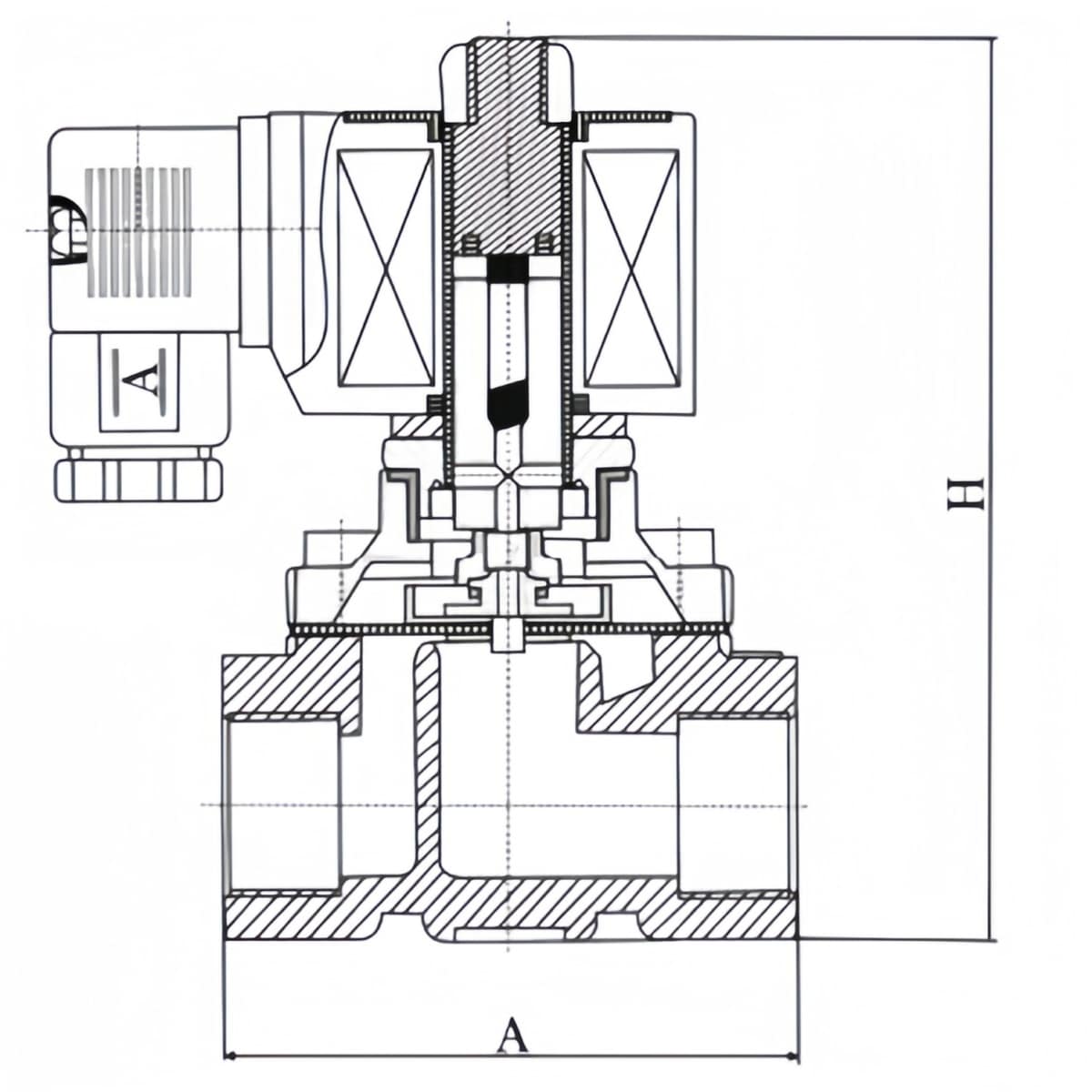

| DN | Thread | Flange | |||

|---|---|---|---|---|---|

| G | A | H | A | H | |

| DN3-8 | G1/8, G1/4 |

47 | 65 | ||

| DN10 | G3/8 | 70 | 135 | ||

| DN15 | G1/2 | 70 | 135 | 100 | 140 |

| DN20 | G3/4 | 85 | 140 | 110 | 145 |

| DN25 | G1 | 95 | 218 | 125 | 155 |

| DN32 | G1-1/4 | 115 | 270 | 140 | 160 |

| DN40 | G1-1/2 | 130 | 275 | 150 | 170 |

| DN50 | G2 | 145 | 205 | 165 | 175 |

| DN65 | 200 | 240 | |||

| DN80 | 240 | 260 | |||

| DN100 | 280 | 295 | |||

| DN125 | 310 | 295 | |||

| DN150 | 460 | 350 | |||

| DN200 | 460 | 350 | |||

Product Description

The VCA vacuum solenoid valve is mainly used in vacuum pipelines or control systems connected with vacuum pumps. It is widely applied in vacuum forming, vacuum packaging, vacuum suction systems, vacuum pumps, and municipal siphon water supply automation systems.

Working Principle

The VCA vacuum solenoid valve is a dedicated valve installed on mechanical vacuum pumps. The valve and the pump share the same power supply: when the pump is switched on, the valve opens; when the pump stops or in case of sudden power failure, the valve automatically closes the vacuum system and allows atmospheric air to enter through the pump inlet. This prevents oil backflow and contamination of the vacuum system.

According to structure and control type, VCA vacuum solenoid valves are available in three versions:

-

Vacuum Holding Type

-

Vacuum Releasing Type

-

High Vacuum Bi-directional Holding Type

Functional Role

The VCA vacuum solenoid valve is designed for operation below atmospheric pressure, creating a certain level of vacuum (negative pressure). It is widely used in vacuum equipment pipelines as an on-off control valve. Typical applications include purified air systems, food processing, metallurgy, and environments with strict leakage requirements. Based on structure and control type, it is available in holding, releasing, and bi-directional holding designs.

Structural Features

-

Operates in direct-acting mode since vacuum conditions cannot initiate pressure-assisted (pilot) operation, unlike conventional solenoid valves.

-

Requires excellent sealing performance; gap sealing is not applicable to ensure high airtightness.

-

Features reverse flow direction suitable for vacuum systems.

-

Valve body is typically made of stainless steel, offering higher durability compared to ordinary solenoid valves.

Technical Parameters

-

Nominal Diameter: DN3–200 mm

-

Body Material: Cast Steel, Stainless Steel

-

Applicable Media: Non-corrosive gases and liquids

-

Medium Temperature: 0–100℃

-

Ambient Temperature: -10–+40℃

-

Vacuum Pressure: 0.1 MPa

-

Power Supply: Available in AC/DC voltages

-

Control Mode: Normally Closed / Normally Open

-

Optional Features: Signal feedback, Explosion-proof design