Ex-Proof Gas Solenoid Valve | Explosion Proof Electromagnetic Valve

The ex-proof gas solenoid valve is specially designed for hazardous and explosive environments. Featuring a robust piston structure and explosion-proof coil, it ensures stable performance, high safety, and reliable control of gas, oil, water, and corrosive media in industrial automation systems.

The valve adopts a durable piston-type structure with an explosion-proof coil, providing excellent resistance to burning, dust, water, and ignition risks. It supports multiple control modes and a wide range of pressures and temperatures, making it ideal for demanding and hazardous working conditions.

-

Type: 2/2-Way

-

Body Material: Forged Brass / Stainless Steel

-

Working Pressure: 0–200 Bar

-

Fluid Media: Gas, Water, Oil, Air

-

Explosion-proof design for hazardous and explosive areas

-

Stable piston structure with long service life

-

High-quality explosion-proof coil, not easy to burn

-

Wide pressure and temperature range

-

Suitable for gas, oil, water, and corrosive media

-

Multiple voltage options for AC and DC power supply

-

Flexible connection types for different installations

How to order

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|

| Series | Port Size | Voltage | Seal Material | Orifice (mm) | Body Material | Operation | Coil Type | Thread Standard |

| AGV | 15 | U2 | N | 15L | B | C | D | N |

| 06: 1/8″ 08: 1/4″ 10: 3/8″ 15: 1/2″ 20: 3/4″ 25: 1″ 35: 1-1/4″ 40: 1-1/2″ 50: 2″ | U1: 110VAC U2: 220VAC U3: 380VAC U4: 24V DC U5: 12V DC U6: 36V AC U7: 24V AC | N: NBR V: VITON E: EPDM T: PTFE | 1L: 1.0 2L: 2.0 3L: 3.0 4L: 4.0 … 10L: 10 15L: 15 … 50L: 50 | B: Brass S1: SS316 S2: SS304 NY: Nylon UP: UPVC | C: Normally Closed O: Normally Open | D: DIN Standard W: Lead Wire X: EX-Proof A: Water-Proof | B: BSP G: G N: NPT |

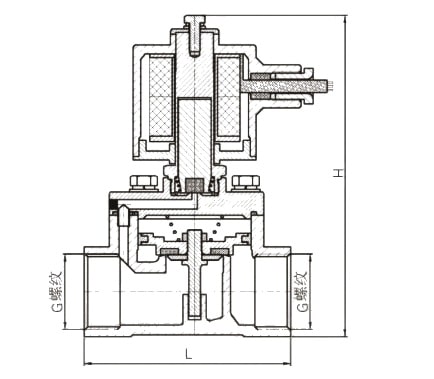

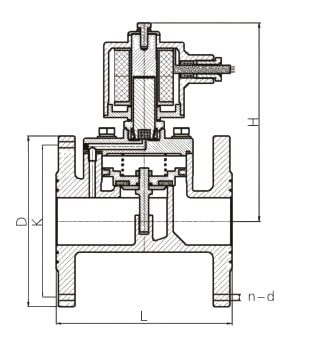

Dimensions

| Size | Female Thread | PN16 Flange (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thread | L | H | Weight (KGS) |

L | H | D | K | n-d | Weight (KGS) |

|

| DN0.5 | G1/8 | 40 | 80 | 0.5 | ||||||

| DN3 | 40 | 95 | 1 | |||||||

| DN5 | 55 | 110 | 2 | |||||||

| DN8 | G1/4 | 60 | 130 | 2 | ||||||

| DN10 | 60 | 130 | 2.2 | |||||||

| DN15 | G1/2 | 70 | 145 | 2.3 | 105 | 150 | Φ93 | Φ65 | 4-Φ14 | 3.5 |

| DN20 | G3/4 | 85 | 155 | 2.5 | 120 | 155 | Φ103 | Φ75 | 4-Φ14 | 4 |

| DN25 | G1 | 95 | 165 | 2.8 | 130 | 165 | Φ114 | Φ85 | 4-Φ14 | 5 |

| DN32 | G1-1/4 | 120 | 175 | 3.5 | 155 | 170 | Φ138 | Φ100 | 4-Φ18 | 6.3 |

| DN40 | G1-1/2 | 130 | 180 | 4.3 | 160 | 180 | Φ148 | Φ110 | 4-Φ18 | 7.5 |

| DN50 | G2 | 145 | 195 | 4.5 | 170 | 185 | Φ163 | Φ125 | 4-Φ18 | 9 |

| DN65 | 230 | 250 | Φ185 | Φ145 | 4-Φ18 | 16 | ||||

| DN80 | 270 | 270 | Φ200 | Φ160 | 8-Φ18 | 21 | ||||

| DN100 | 300 | 305 | Φ220 | Φ180 | 8-Φ18 | 31 | ||||

| DN125 | 380 | 305 | Φ250 | Φ210 | 8-Φ18 | 41 | ||||

| DN150 | 420 | 360 | Φ285 | Φ240 | 8-Φ23 | 56 | ||||

| DN200 | 460 | 390 | Φ340 | Φ295 | 12-Φ23 | 140 | ||||

| DN250 | 650 | 430 | Φ405 | Φ355 | 12-Φ26 | 190 | ||||

| DN300 | 750 | 500 | Φ460 | Φ410 | 12-Φ26 | 300 | ||||

| DN350 | 850 | 540 | Φ520 | Φ470 | 16-Φ26 | 420 | ||||

| DN400 | 950 | 590 | Φ580 | Φ525 | 16-Φ30 | 560 | ||||

| DN450 | 1050 | 630 | Φ640 | Φ585 | 20-Φ30 | 700 | ||||

| DN500 | 1150 | 670 | Φ710 | Φ650 | 20-Φ33 | 890 | ||||

Technical Data Sheet

| Item | Specification |

|---|---|

| Product Type | Ex-proof gas solenoid valve |

| Control Mode | Normally Open (NO) / Normally Closed (NC) / Latching |

| Power Supply | DC 12–220V / AC 24–380V |

| Valve Body Material | Carbon steel / Brass / Aluminum / Stainless steel / PTFE |

| Applicable Media | Gas / Water / Oil / Corrosive fluids |

| Pressure Range | 0 – 200 MPa |

| Temperature Range | –200°C to +600°C (depending on configuration) |

| Medium Viscosity | ≤ 50 cSt (custom available) |

| Protection Class | Explosion-proof / Dustproof / Waterproof |

| Connection Type | Flange / Welding / Threaded |

| Electrical Connection | DIN Connector / Lead wire |